THE NEW DENTAL LABORATORY | Technical Article

Fabio Scarano Catanzaro – Dentist, Bari, Italy

Filippo Squicciarini – Dental Technician, Bari, Italy

Roberto Felice Grassi – Dentist, Bari, Italy

Introduction

This article presents the clinical and laboratorial procedure for performing an immediate –load implant rehabilitation, using B&B Dental’s guided surgery systems.

The scan data was acquired via with an intraoral scanner. The facial scan was performed through photogrammetry using a smartphone video.

Digital workflows in dentistry have greatly facilitated full-arch rehabilitations. The fast exchange of information between the clinic and laboratory, and the sheer volume of data available, significantly reduces the margin of error.

Case Description

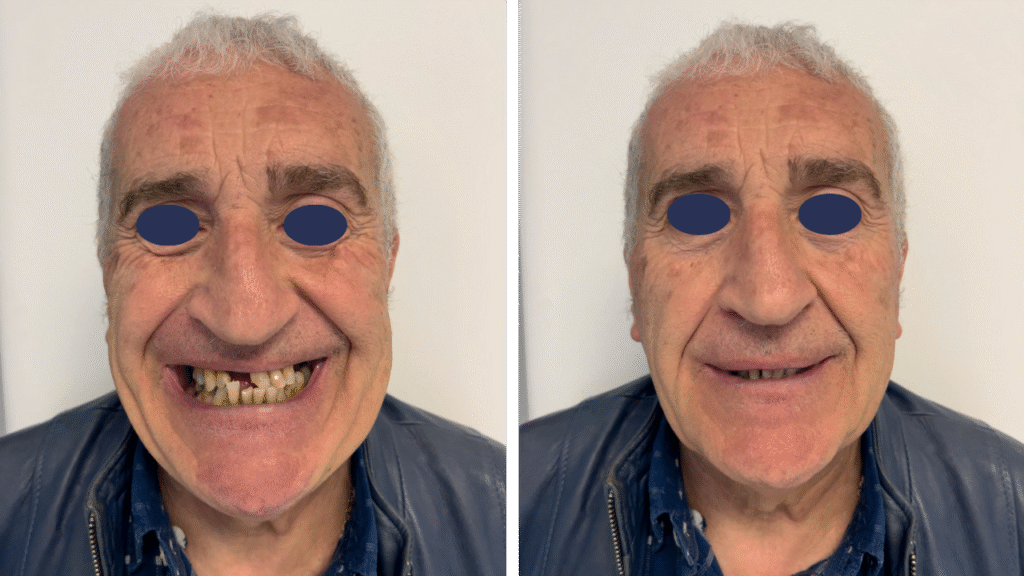

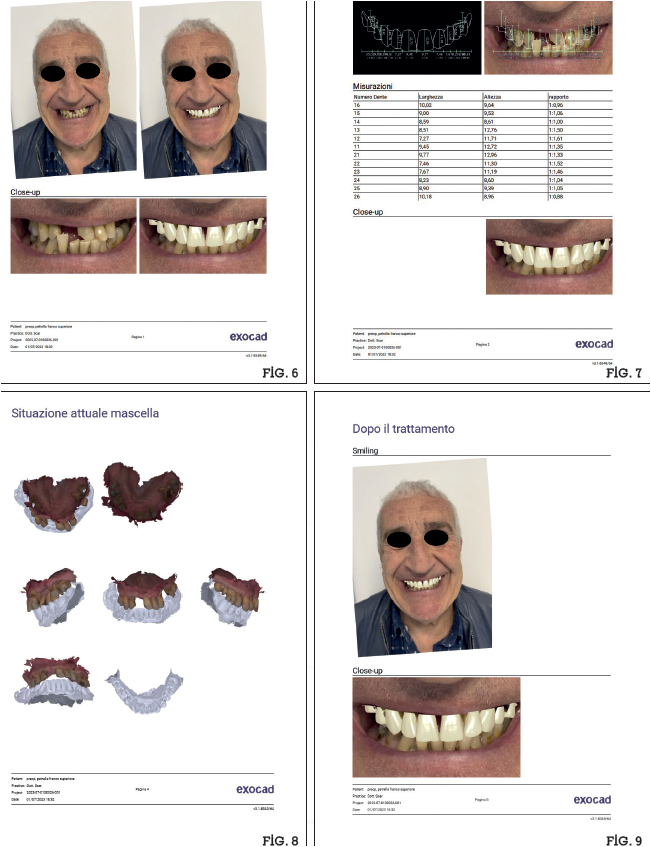

The patient, Mr. Franco, a 66-year-old Caucasian male in good general health, presented with tooth mobility, persistent pain, and difficulty chewing. Clinical evaluation revealed missing anterior and posterior teeth, with Grade I and II mobility in all upper teeth, and significant tartar and plaque accumulation.

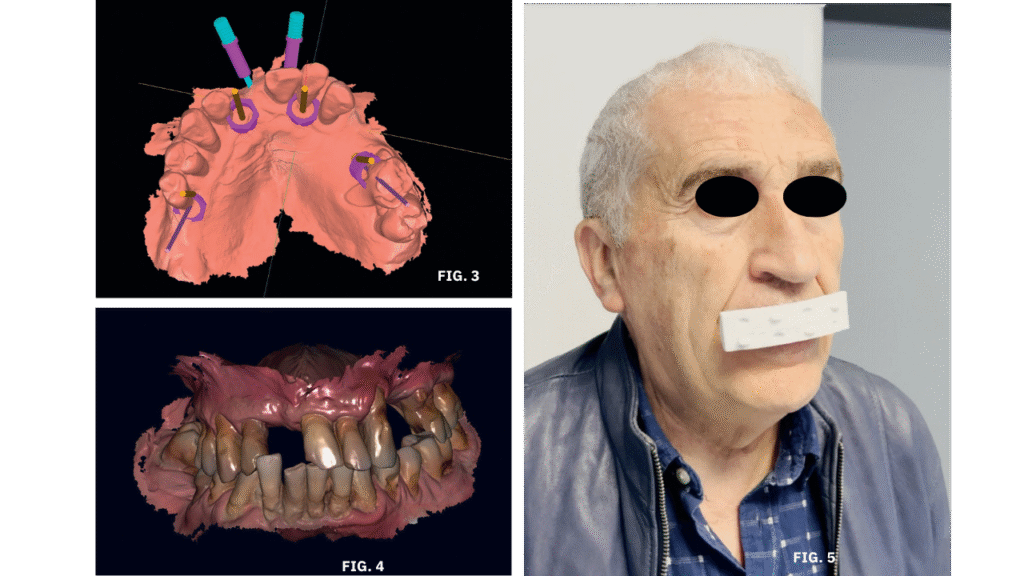

Following a professional hygiene session and oral hygiene instruction, a CBCT scan was performed for implant planning using B&B Dental software. Intraoral scans were acquired to record the patient’s centric relation—crucial data for the restoration. A 12-second smartphone video was recorded to generate a 3D facial scan using photogrammetry.

In the upper arch, the plan included extraction of all teeth and placement of four implants in positions 12, 22, 15, and 26, followed by immediate prosthetic loading. For the lower arch, the most compromised teeth would be extracted first, followed by a temporary removable denture to stabilize and balance occlusion, with full implant rehabilitation planned after three months.

Digital Planning & Simulation

With biometric data collected and sent to the lab, an initial 2D aesthetic simulation was created for the patient, combining guided implant planning, intraoral scanning, and prosthetic modeling using exocad.

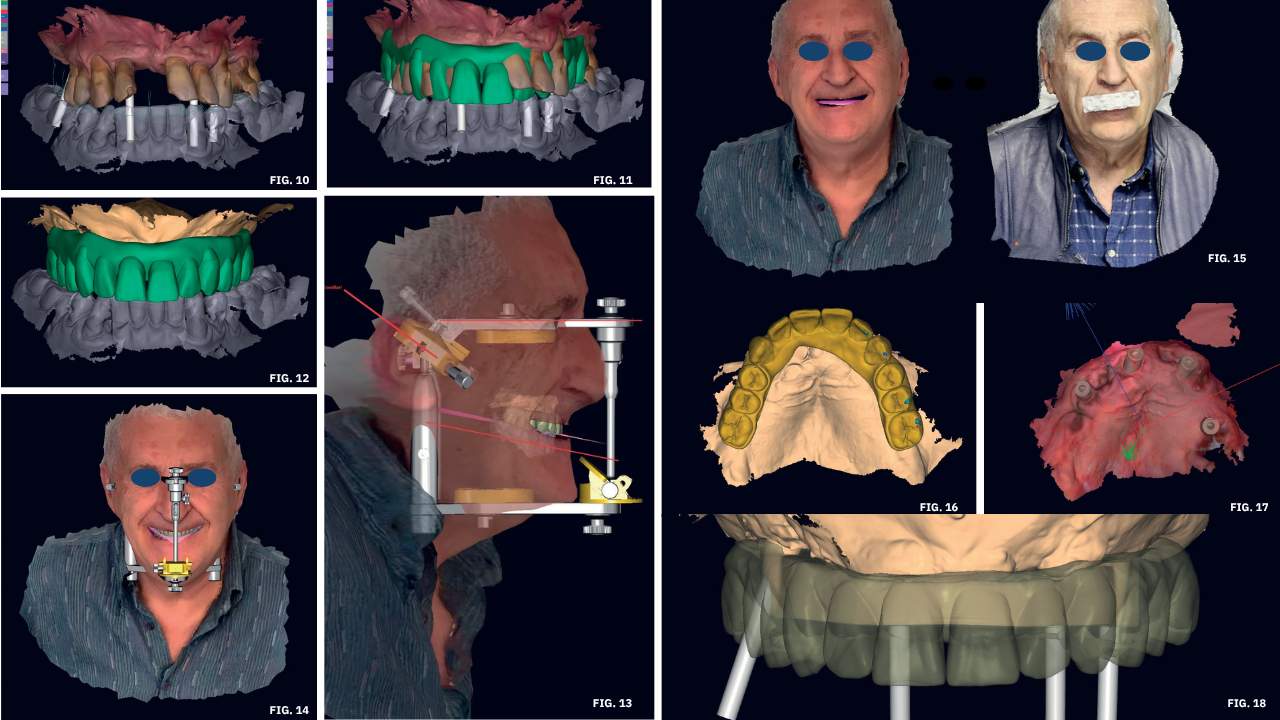

Once the treatment plan and aesthetics were approved, the lab began a virtual diagnostic wax-up, increasing the vertical dimension by approximately 1 mm in the virtual articulator. The maxillary and mandibular models were aligned using the patient’s 3D facial scan and anatomical landmarks (e.g., condylar reference to the tragus and interpupillary line), setting incisal guidance and condylar inclination at 40°.

Facial and intraoral scans were merged using the modeling software’s matching feature. The facial scan with marker was aligned with the maximum smile scan. Intraoral scans were then aligned with the face using a fork reference

Surgical Phase and Prosthesis Design

On the day of surgery, under local anesthesia (Articaine 4%, epinephrine 1:100000), the remaining teeth were atraumatically extracted. Guided surgery was performed to place EV B&B Dental implants, as planned. Multi-unit abutments (MUAs) were placed, and scan bodies acquired to match with the pre-designed diagnostic wax-up.

Finalization and Delivery

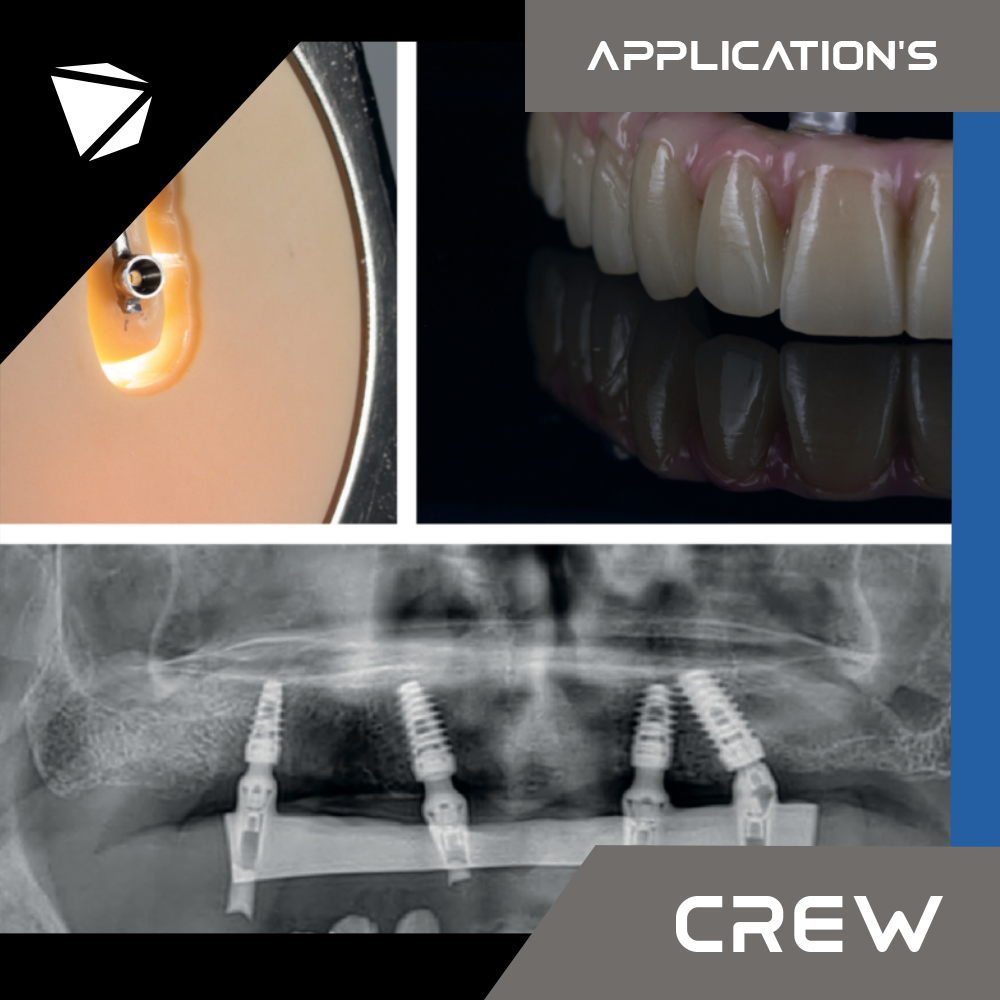

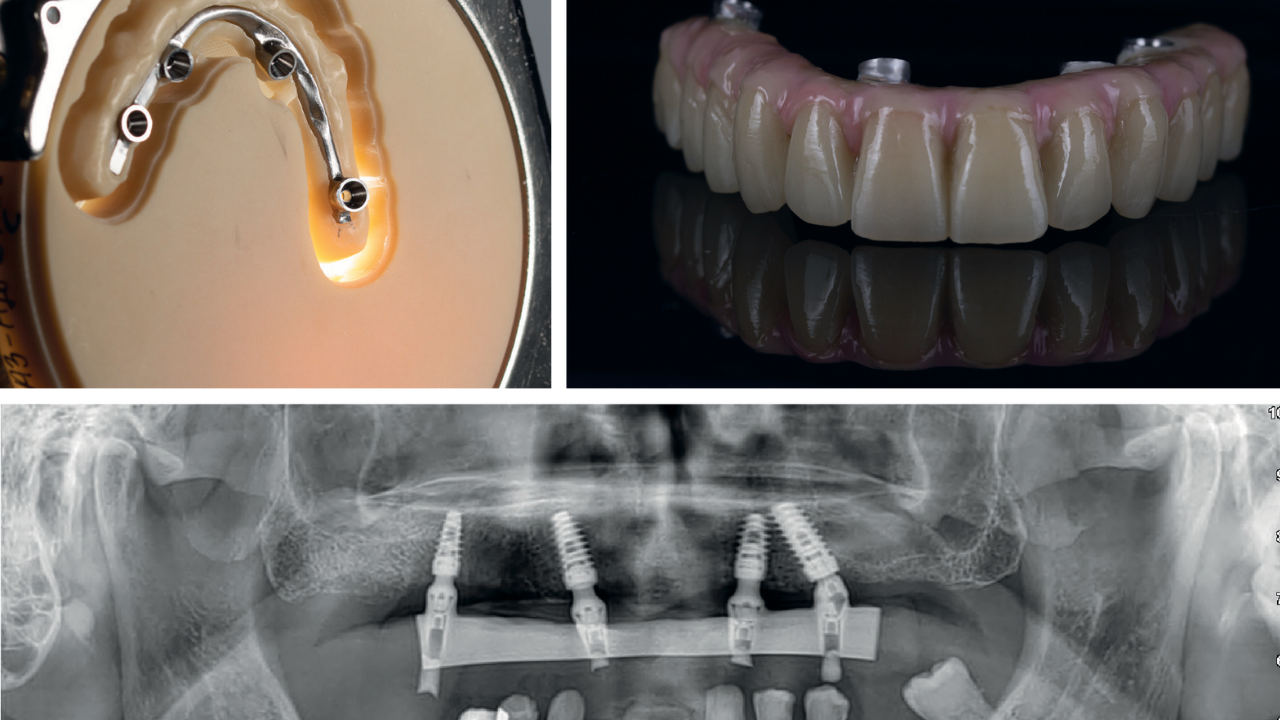

The designed framework was a 2° angulated titanium bar, screwed directly into the implants. The aesthetic overlay was milled in PMMA.

The patient later chose not to proceed with the mandibular rehabilitation. After six months, tissue conditioning was performed to compensate for physiological recession due to immediate loading. Acrylic resin was added in the incisal surface to prepare for the permanent prosthesis.

After tissue stabilization, new digital impressions with scan bodies were taken. Within 4–6 hours, both the titanium bar and PMMA superstructure were milled. Before final bonding, a test fit of the titanium bar was performed to ensure passive fit and allow for refinements.

The PMMA was removed from the jig, and opaque “salt-and-pepper resin” was used to bond the bar to the overlay. Special attention was given to creating a convex labial surface for proper tissue compression and hygiene.

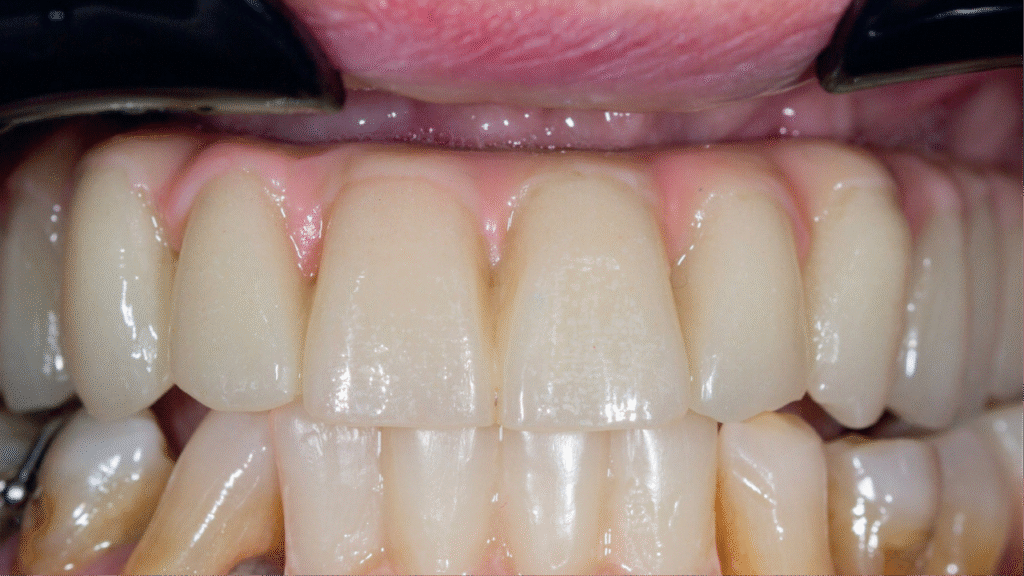

Final customization included pink resin characterization with pigments to give the prosthesis a natural appearance. Post-delivery, a radiograph confirmed correct fit, and soft tissue integration was assessed.

The treatment concluded with pre- and post-operative extraoral photos.

The Authors

Fabio Scarano Catanzaro

Graduated in Dentistry and Dental Prosthetics from Aldo Moro University of Bari. Holds a second-level Master’s in Periodontology and Advanced Surgery. Speaker at numerous national and international congresses and advanced theoretical-practical courses in oral surgery and implantology.

Filippo Squicciarini

Graduated as a dental technician in 2009 from I.P.S.I.A. “L. Santarella” in Bari. Owner of Zirkonlab in Santeramo in Colle since 2012. Specialized in digital techniques and expert in exocad software. Proficient in design tools like ZBrush, Meshmixer, and Rhino.

Roberto Felice Grassi

Full Professor at the CLSOPD of the University of Bari. Former Director of the Departments of Dentistry and Surgery, and Clinical Methodology. Assistant Professor at the University of New York – Buffalo, and Adjunct Associate Professor at the University of Medicine & Dentistry, New Jersey. Visiting Professor at the University of Michigan – Ann Arbor.

DGSHAPE sincerely thanks ANTLO for the kind permission to publish this real case content, and Filippo Squicciarini for his valuable contribution.

DGSHAPE sincerely thanks ANTLO for the kind permission to publish this real case content, and Filippo Squicciarini for his valuable contribution.

Filippo Squicciarini, one of the DGSHAPE Experts and an active member of ANTLO (National Association of Italian Dental Technicians), is a passionate and experienced user of DGSHAPE technology. His lab is equipped with a 5-axis DWX milling machine Equipped with an open CAD/CAM system, 6-slot Automatic Disc Changer, and 15-station Automatic Tool Changer.