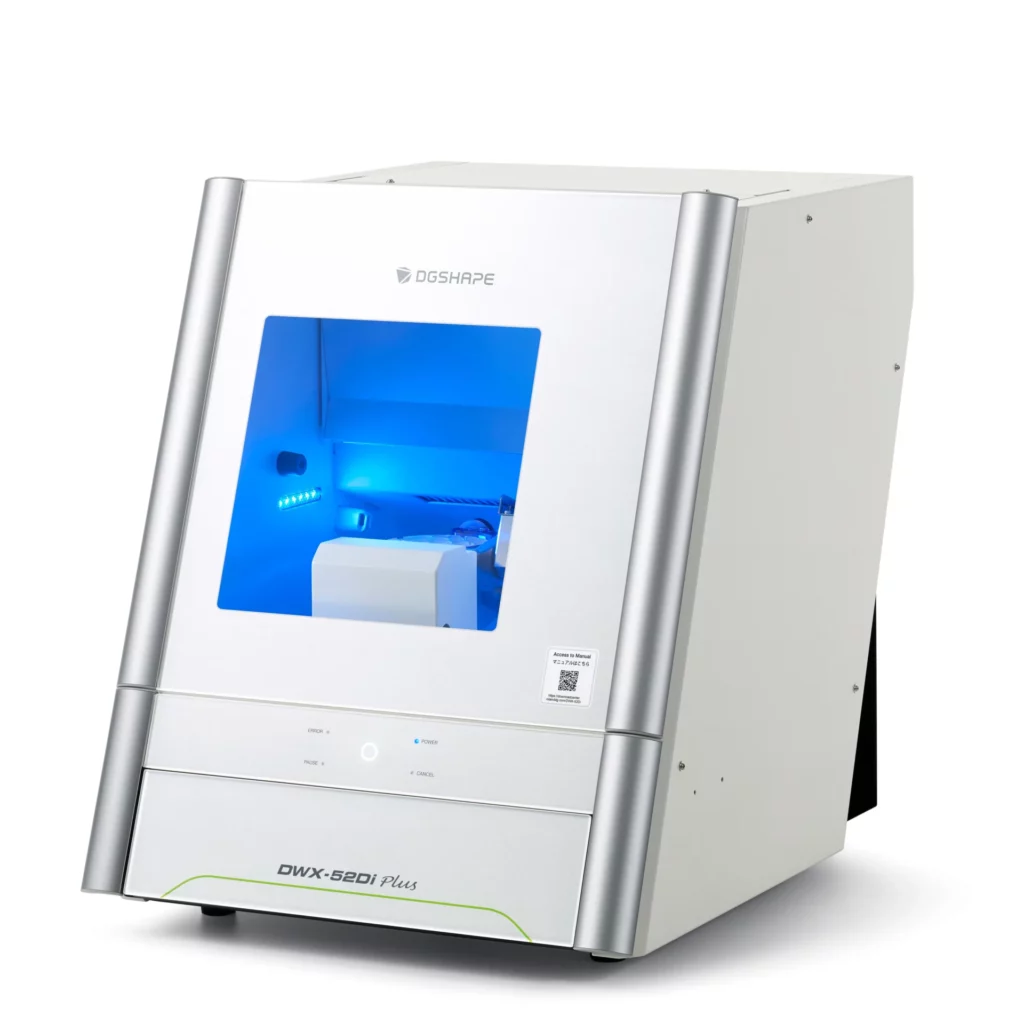

Entry Level 5-Axis DRY

Dental Milling Machine

PREMIUM QUALITY WITHOUT THE PREMIUM PRICE

Entry Level 5-Axis DRY

Dental Milling Machine

PREMIUM QUALITY WITHOUT THE PREMIUM PRICE

Advantages of Choosing the DWX-52Di Plus

Save time and costs with the 5-Axis DWX-52Di Plus dental milling machine and its entry-level price!

Cost-effective with high quality, the DWX-52Di Plus’s 5-axis milling technology is a precise and efficient dental restoration solution, allowing users to produce a wide range of restorations, including crowns, copings, bridges, inlays, onlays, veneers, abutments, implant bars, and screw-retained crowns.

Its upgraded user-replaceable spindle and C-type clamp are also compatible with disc- and pin-type materials, enhancing the machine’s efficiency and versatility.

C-type Clamping System

Entry-Level Price

Mill Up to 8 Pin-Type Blocks

Open CAD/CAM System

90° Milling Range

5-Axis Dental Milling

Millable Materials

- Zirconia

- Wax

- PMMA

- Composite resin

- PEEK

- PEKK

- Gypsum

- Glass fiber reinforced resin

- CoCr sinter metal

- Polycarbonate

Millable Material

Discover the Variety of Materials You Can Mill with Your New DWX-52Di Plus.

- Zirconia

- Wax

- PMMA

- Composite Resin

- PEEK

- PEKK

- Gypsum

- Polycarbonate

- Glass fiber reinforced resin

- CoCr sinter metal

Millable Applications

Discover the Range of Applications You Can Create with Your DWX-52Di Plus.

Whether you’re crafting dental crowns, bridges, or custom implants, this advanced technology ensures exceptional quality and consistency in every piece.

With the DWX-52Di Plus, you can explore a wide range of dental applications, all produced with the highest standards of accuracy and detail.

Inlay

Onlay

Overlay

Crown

Veneer

DGSHAPE stands out as one of the finest in its field compared to other devices.

It is highly regarded, especially in Algeria, for its strength and performance.

Shamia Ahmed – Dental Ouest

Highlights

Advanced and Versatile Milling with an Enhanced Spindle

The DWX-52Di Plus’s robust system with its re-engineered spindle enables stable and fast milling of a wide variety of materials, including zirconia, PMMA, wax, composite resin, PEEK, PEKK, gypsum, glass fiber reinforced resin, and CoCr sinter metal, etc.

The user-replaceable spindle reduces downtime and cost, offering a lower total cost of ownership and a quicker return on investment.

C-type Clamp Compatible with Pin-type Blocks

The optional pin-type material adapter enables milling of up to eight pin-type blocks simultaneously.

Better Anterior Esthetics with 90-degree Milling

The C-type clamp system enhances functionality with a 90-degree milling range, allowing for improved restoration esthetics. *

*Designed with flexibility in mind, our milling solutions adapt to regional preferences while maintaining exceptional overall performance. Contact your local representative for details.

Advanced and Versatile Milling with an Enhanced Spindle

The DWX-52Di Plus’s robust system with its re-engineered spindle enables stable and fast milling of a wide variety of materials, including zirconia, PMMA, wax, composite resin, PEEK, PEKK, gypsum, glass fiber reinforced resin, and CoCr sinter metal, etc.

The user-replaceable spindle reduces downtime and cost, offering a lower total cost of ownership and a quicker return on investment.

C-type Clamp Compatible with Pin-type Blocks

The optional pin-type material adapter enables milling of up to eight pin-type blocks simultaneously.

Better Anterior Esthetics with 90-degree Milling

The C-type clamp system enhances functionality with a 90-degree milling range, allowing for improved restoration esthetics. *

*Designed with flexibility in mind, our milling solutions adapt to regional preferences while maintaining exceptional overall performance. Contact your local representative for details.

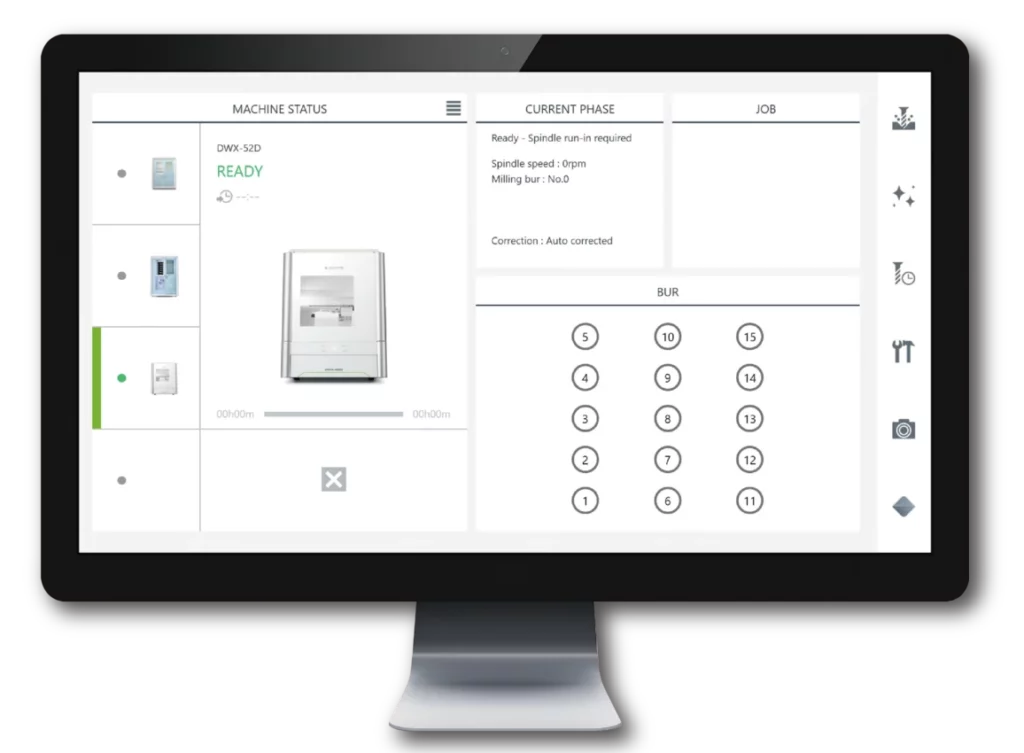

VPanel for DWX

User- and Eco-Friendly Operations

VPanel for DWX seamlessly provides maintenance oversight and output performance control. The Intelligent Tool Control automatically swaps out tools when they have reached their user-defined lifespan.

The DWX-52Di Plus is an energy-efficient, environmentally friendly dental mill that minimizes power consumption while delivering top performance.

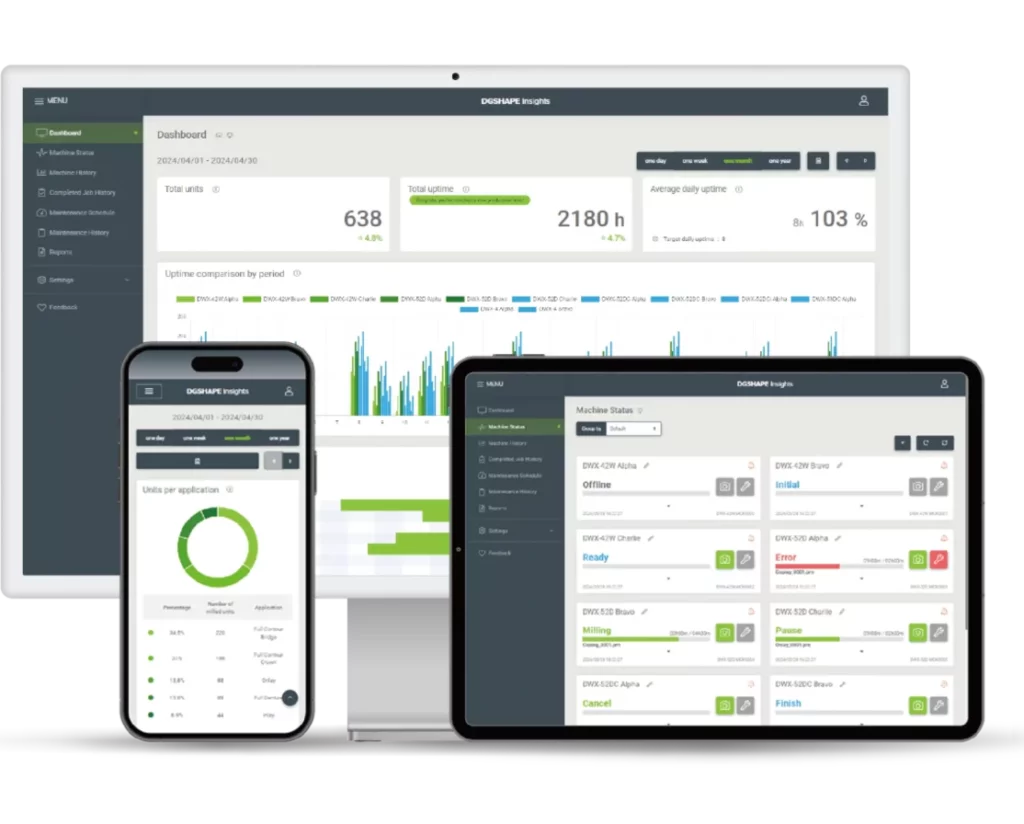

Stay Tuned-In to Tune-Up with DGSHAPE CLOUD

DGSHAPE offers remote monitoring for all DWX devices through its management software, available in DGSHAPE CLOUD. You can monitor machine status anytime, anywhere, while accessing valuable data, maintenance support, and actionable insights for optimal operations.

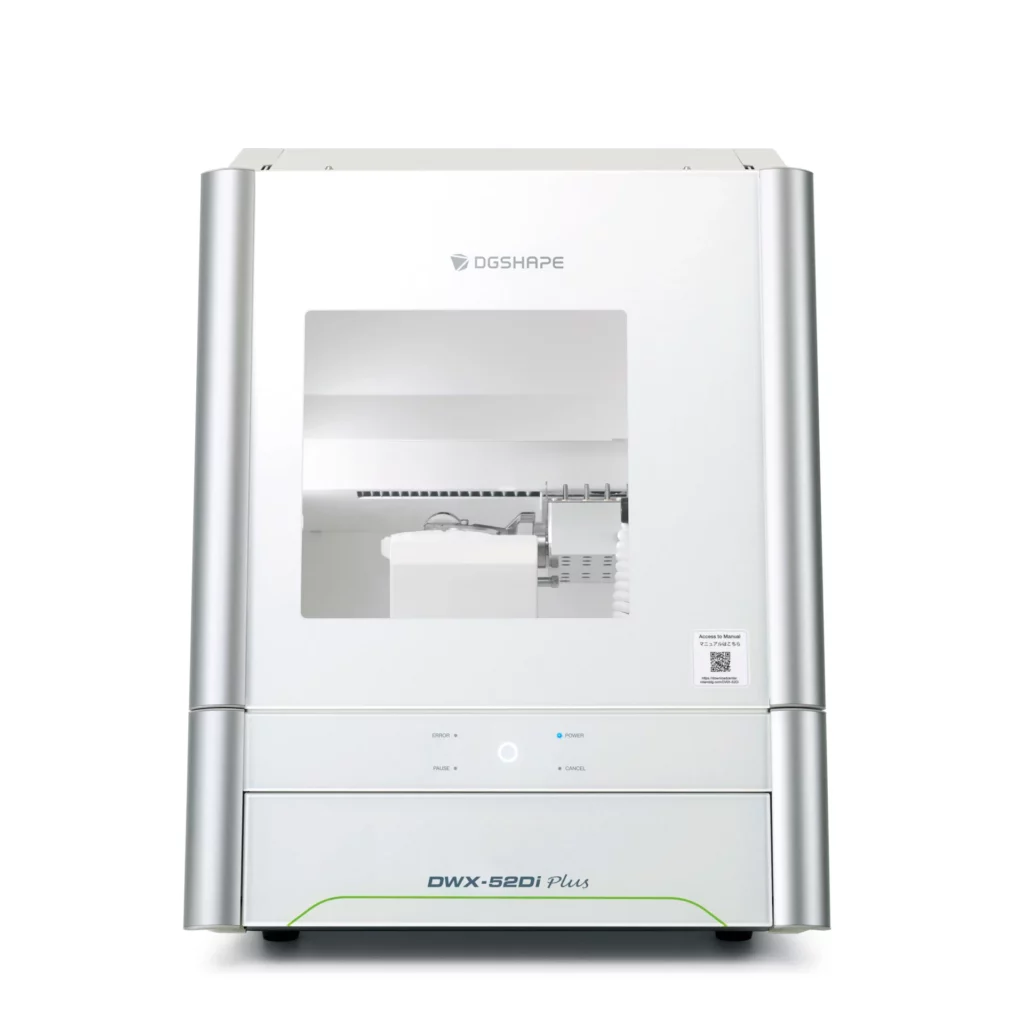

Technical information

67 kg (147.7 lbs.)

Width 495 mm (19.5 in.) x Depth 660 mm (26.0 in.) x Height 600 mm (23.6 in.)

- Disc-type:

Step section: 98.5 mm (3.88 in.) (diameter), height 10mm (0.39 in.)

Body section: 95 mm (3.47 in.) (diameter), height max. 60mm (2.36 in.)

- Pin type:

Pin diameter: 6 mm (0.24 in.)

*The optional pin-type material adapter ZV-52D is required.

Operating speed: XYZ axis 6 to 1,800 mm/min (0.24 to 70.9 in/min)

Spindle rotating speed: 6,000 to 30,000 rpm

Rotary axis travel angle: A ±360°, B ±30°

Up to 15 pieces

Shank diameter: 4 mm (0.16 in.)

Length: 40 to 55 mm (1.57 to 2.17 in.)

Interface: USB

Power requirements: AC 100 V to 240 V ±10%, 50/60 Hz (overvoltage category II, IEC60664-1), 2.0 A

Power consumption: approx. 200 W

ZC-4D collet replacement

ZS-4D spindle replacement

ZSB-170/140 spindle belt

Frequently Asked Questions

Mainly for three reasons: the quality of the machinery, our milling machines have a very long lifecycle; the quality of the produced applications, the lifecycle of the tools and ease of use.

Our decision to separate dry from wet milling production stems from the idea of providing our customers with dental milling machines that are easy to use, require little maintenance, and have the fewest possible issues during their lifecycle.

All our DGSHAPE milling machines have an open CAD/CAM system, allowing the machine owner to use their preferred software.

Please, contact your resellers for details.

The warranty provided directly by DGSHAPE lasts for one year.

The dealer from whom the customer purchases the machine may offer any warranty extensions. Additionally, DGSHAPE provides a customer support subscription service.

One of the strengths of DGSHAPE dental milling machines is their ease of use, from calibration to maintenance.

We at DGSHAPE do not directly provide courses, but usually, it’s our trained dealers who offer assistance and courses from the initial installation.

Finally, we have tutorials on our website and YouTube channel.

Through our network of dealers, we are present in over 200 countries.

In addition, DGSHAPE has direct subsidiaries in the main countries where it operates, ensuring comprehensive support in the local language.

We firmly believe in the quality of our machinery, which is why DGSHAPE provides spare parts for its dental milling machines at a reasonable cost.

Additionally, it allows for easy replacement of the spindle, which can be done autonomously by the machine owner.

Contact Us

Demo

Would you like to request a free demo?

Fill out our form to discover the best

solution for your business.

Quote

Are you interested in one of our dental milling machines?

Fill out the form and we’ll send you a quote.

Consultation

Do you want to speak with our experts?

Fill out the form and we’ll contact you as soon as possible.

Our DGSHAPE authorized dealers are carefully selected, and offer superior expertise and tailored advice across a range of DGSHAPE products and services

By filling out the form, we ensure

- Quick dealer contact

- Expert dealer matching for your country

- Time-saving dealer search

- Authentic DGSHAPE products and services

DGSHAPE A Roland DG Group Company

Roland DG Group Company has been the benchmark for advanced machine manufacturing for over 38 years, thanks to its practical and reliable technology with unmatched support.

DGSHAPE continues and enhances this legacy, making it easier and more effective for laboratories and clinics to produce high-quality, cost-effective dental prosthetics.