Meet KEN.DENTALX

Meet KEN.DENTALX

KEN.DENTALX is a dental laboratory based in Tokyo, Japan. Founded in 1980, KEN.DENTALX has been offering dental restorations for more than 40 years.

Of the 55 dental technicians working at KEN.DENTALX, 15 are responsible for CAD/CAM milling. The CAD/CAM milling process is divided to improve the efficiency, and they achieved high productivity. Also, they have actively invested on the digital equipment to enhance their technique.

Their experienced staff and advanced digital technology produce dental restorations that are highly rated and sought after clinics across Japan.

KEN.DENTALX employs a wide range of digital equipment including scanners, 3D printers and milling machines. They have been using DGSHAPE’s DWX series milling machines for many years.

They began using data-driven operation management when DGSHAPE Insights was still DWINDEX2. Now, they use DGSHAPE Insights to help them achieve high DWX milling performance.

KEN.DENTALX is a dental laboratory based in Tokyo, Japan. Founded in 1980, KEN.DENTALX has been offering dental restorations for more than 40 years.

Of the 55 dental technicians working at KEN.DENTALX, 15 are responsible for CAD/CAM milling. The CAD/CAM milling process is divided to improve the efficiency, and they achieved high productivity. Also, they have actively invested on the digital equipment to enhance their technique.

Their experienced staff and advanced digital technology produce dental restorations that are highly rated and sought after clinics across Japan.

KEN.DENTALX employs a wide range of digital equipment including scanners, 3D printers and milling machines. They have been using DGSHAPE’s DWX series milling machines for many years.

They began using data-driven operation management when DGSHAPE Insights was still DWINDEX2. Now, they use DGSHAPE Insights to help them achieve high DWX milling performance.

How KEN.DENTALX achieved extraordinary DWX utilization

How KEN.DENTALX achieved extraordinary DWX utilization

Before trying to improve our DWX machines’ productivity, we took steps to improve our DWX machines’ performance. We worked with staff upstream and downstream of the milling process to fix problems the DWX machines encountered. We tried to clarify “Why does the DWX show an error?” and “What caused the error?” Through this process, we were able to identify which milling settings tend to trigger errors and how the state of the machine and its tools influence the milling results.

This process allowed us to forecast the probability of certain types of errors. Based on the error probability forecast, we were able to mill the projects that have a lower error probability at night, and mill those which have a higher probability of errors in the daytime. Our milling machines have automatic disc changers, so it was important to be able to maximize their potential.

Also, we discovered that some problems like “chipping” were caused by the milling burs’ usage time. So we adjusted the milling bur lifetime management guidelines to maintain high quality milling outcomes.

Before trying to improve our DWX machines’ productivity, we took steps to improve our DWX machines’ performance. We worked with staff upstream and downstream of the milling process to fix problems the DWX machines encountered. We tried to clarify “Why does the DWX show an error?” and “What caused the error?” Through this process, we were able to identify which milling settings tend to trigger errors and how the state of the machine and its tools influence the milling results.

This process allowed us to forecast the probability of certain types of errors. Based on the error probability forecast, we were able to mill the projects that have a lower error probability at night, and mill those which have a higher probability of errors in the daytime. Our milling machines have automatic disc changers, so it was important to be able to maximize their potential.

Also, we discovered that some problems like “chipping” were caused by the milling burs’ usage time. So we adjusted the milling bur lifetime management guidelines to maintain high quality milling outcomes.

What was the motivation behind the lab efficiency improvement actions?

What was the motivation behind the lab efficiency improvement actions?

The primary reason we wanted to increase our efficiency was because of an increase in our order volume. Thankfully, the number of requests we receive is increasing day by day through word of mouth referrals from clinics. Also, the widespread adoption of IOS has encouraged digitalization across the dental market, and increasing amount of data makes it essential that we provide highly accurate dental prostheses in a timely manner.

The primary reason we wanted to increase our efficiency was because of an increase in our order volume. Thankfully, the number of requests we receive is increasing day by day through word of mouth referrals from clinics. Also, the widespread adoption of IOS has encouraged digitalization across the dental market, and increasing amount of data makes it essential that we provide highly accurate dental prostheses in a timely manner.

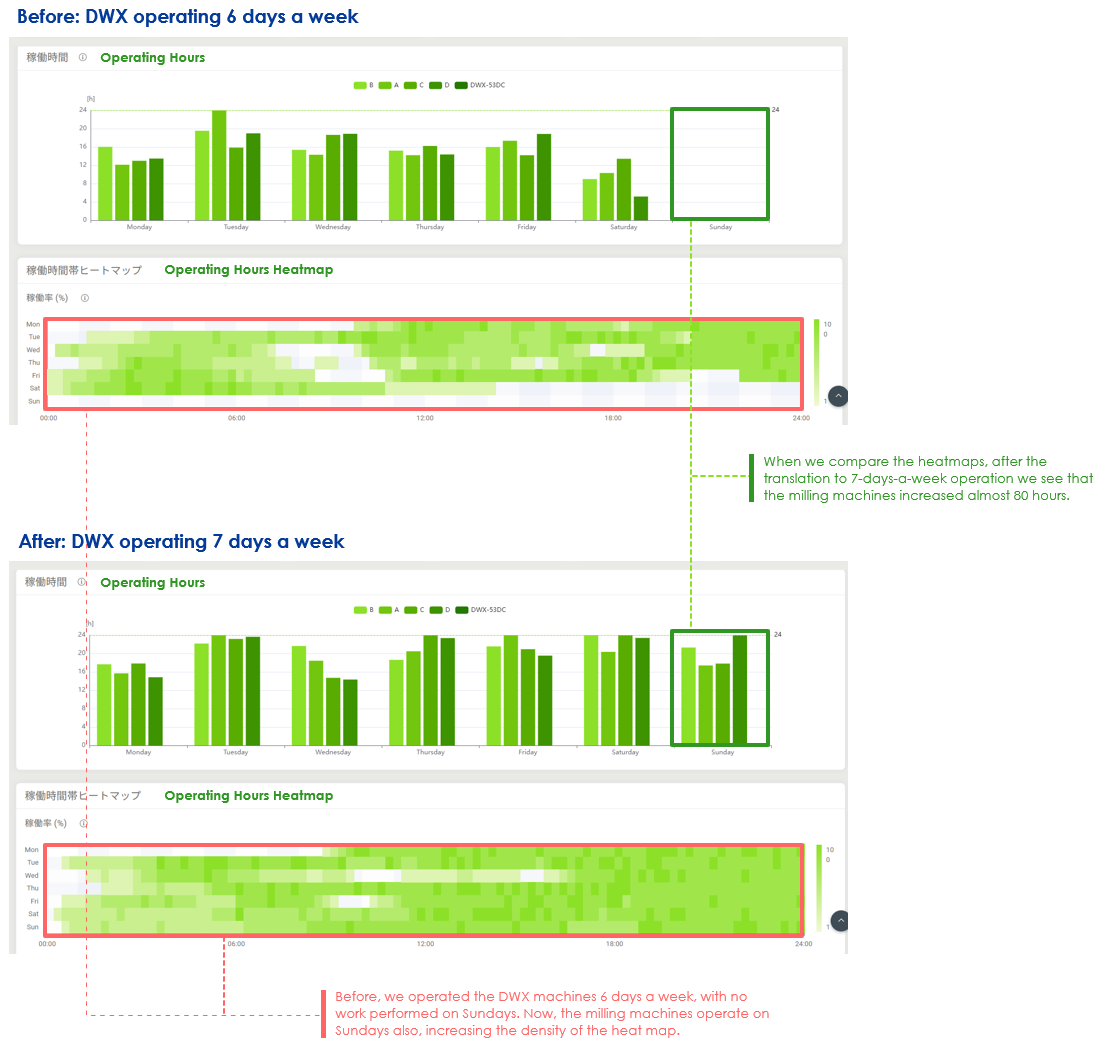

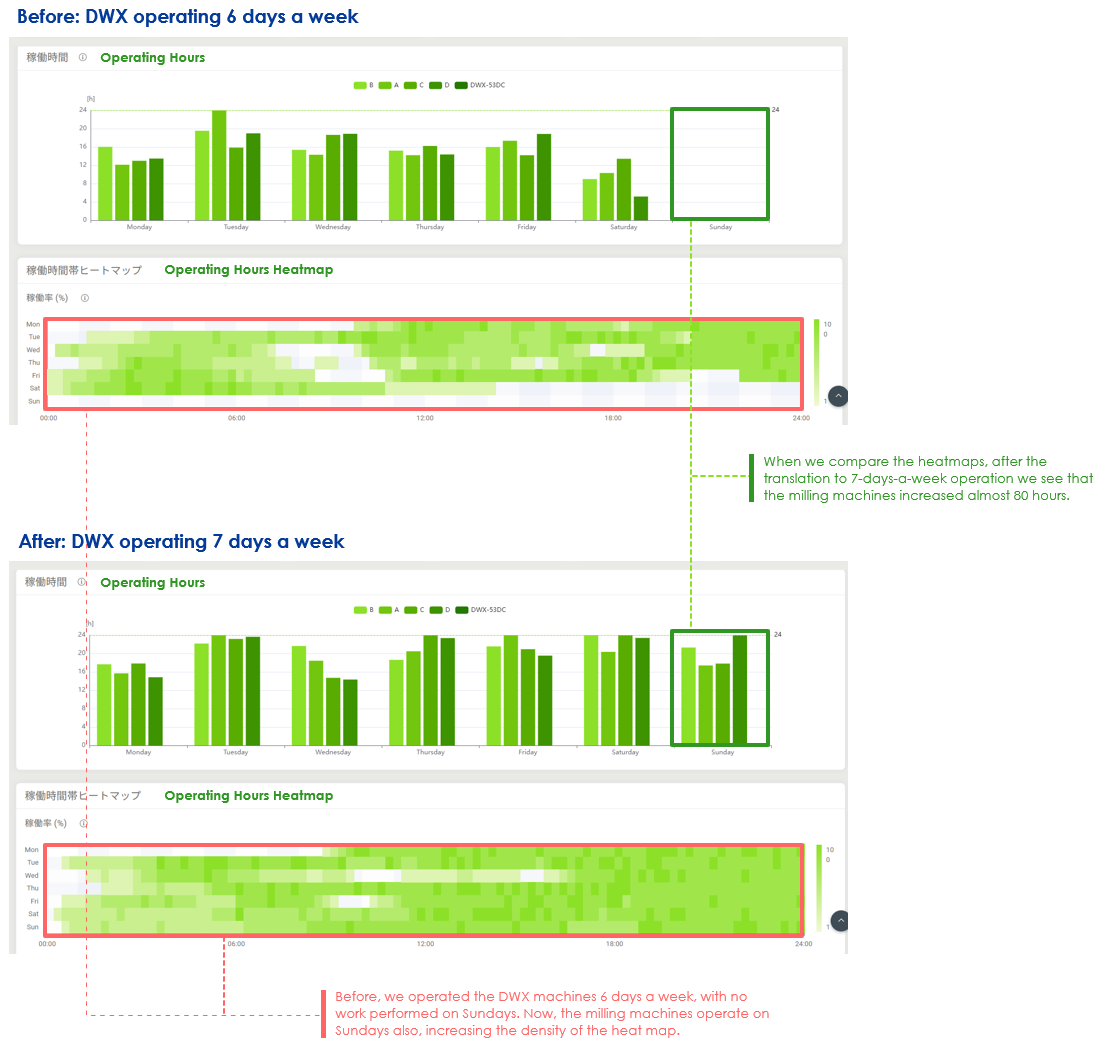

Successful workflow transformation: DWX can operate 7 days a week

Successful workflow transformation: DWX can operate 7 days a week

Also, we tried 6 days operation in a week to meet the increasing demand. Our lab used to operate 5 days a week. Without changing the condition of a 5-day workweek for our staff, we have shifted the lab’s operation to 6 days a week. It enabled us to operate DWX 7 days a week, and the productivity of the lab increased. The fact that many skilled dental technicians are part of our lab made it possible.

Also, we tried 6 days operation in a week to meet the increasing demand. Our lab used to operate 5 days a week. Without changing the condition of a 5-day workweek for our staff, we have shifted the lab’s operation to 6 days a week. It enabled us to operate DWX 7 days a week, and the productivity of the lab increased. The fact that many skilled dental technicians are part of our lab made it possible.

How DGSHAPE Insights contributes to lab efficiency improvements

How DGSHAPE Insights contributes to lab efficiency improvements

DGSHAPE Insights helps us start our daily operations smoothly. By checking DGSHAPE Insights quickly on the way to the lab, we can plan the most productive use of our DWXs’ capabilities.

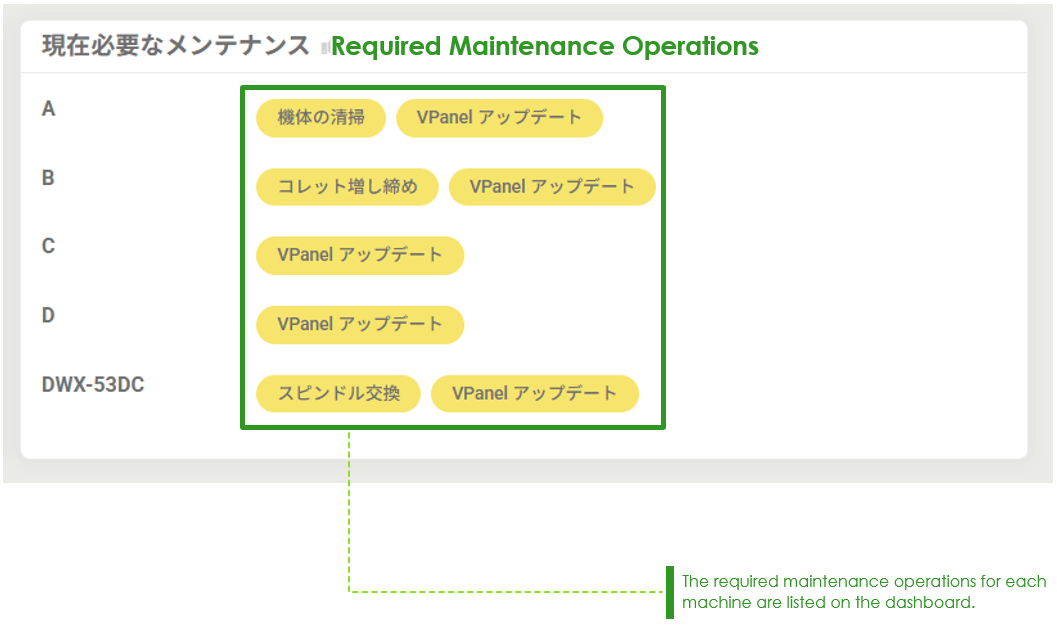

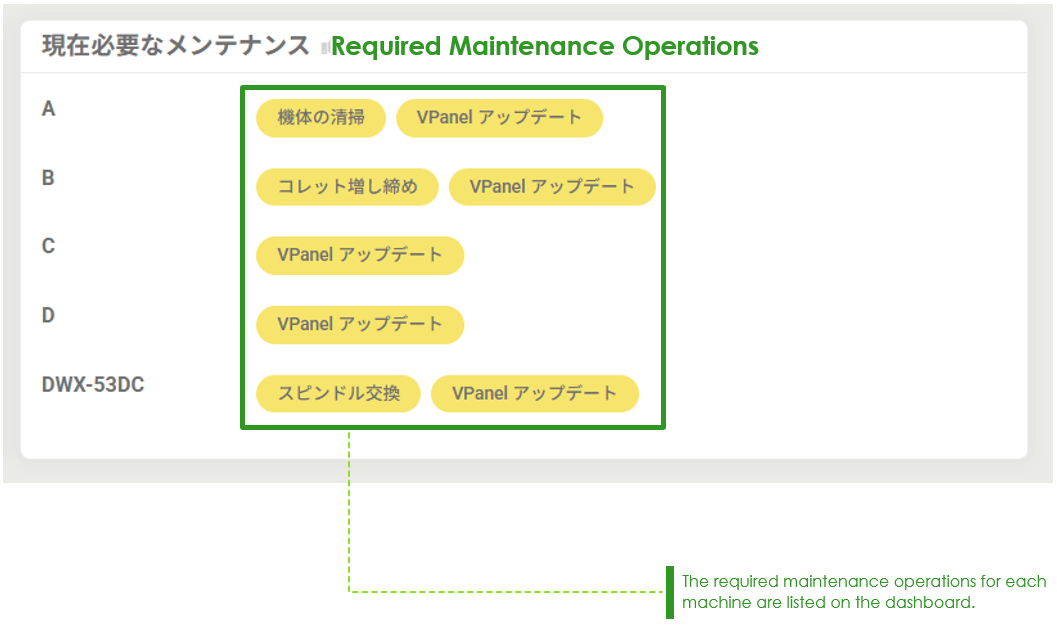

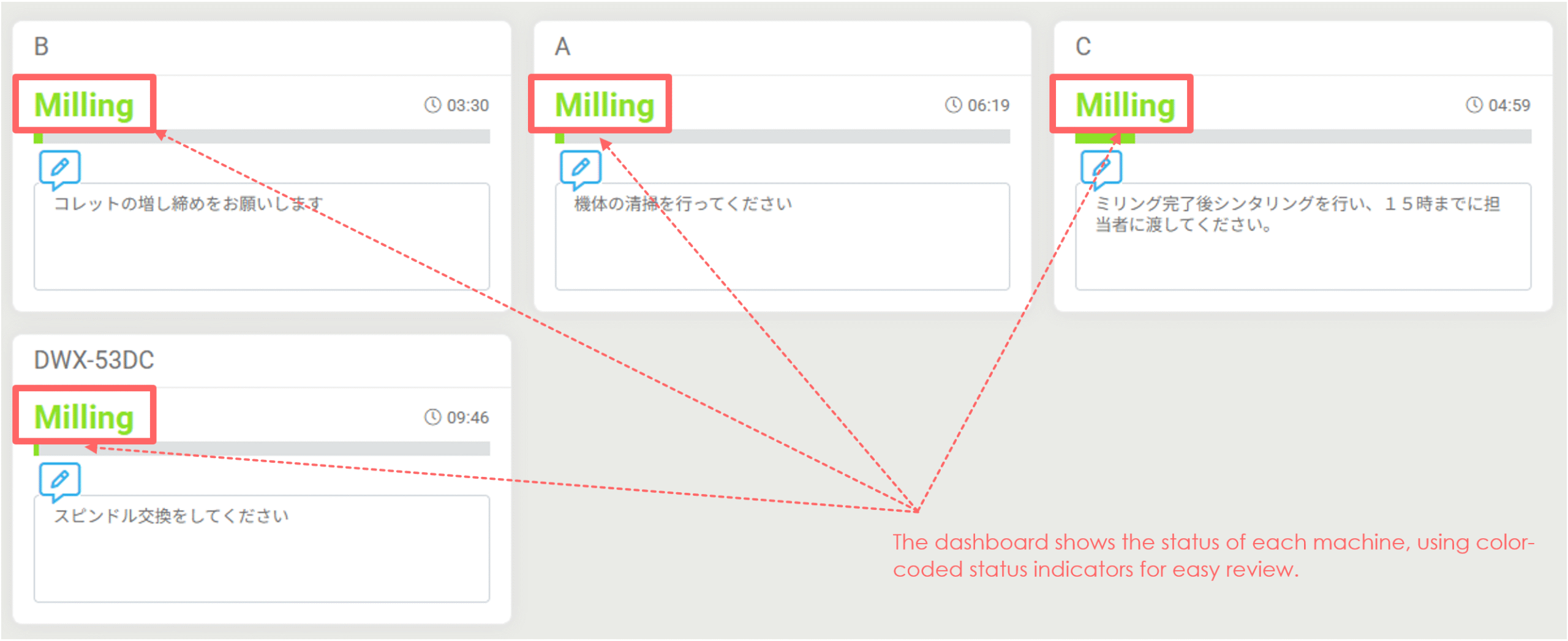

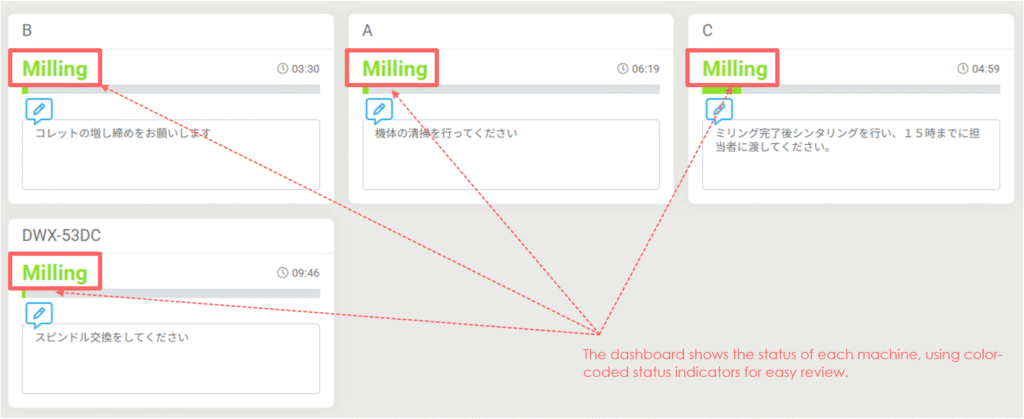

We often check the dashboard which shows the maintenance requirements for each machine in one place, and helps us schedule and conduct the needed maintenance procedures. Also, the status for each machine is color-coded, which helps us instantly see whether milling has been completed and check the current condition of each machine at a glance.

DGSHAPE Insights helps us start our daily operations smoothly. By checking DGSHAPE Insights quickly on the way to the lab, we can plan the most productive use of our DWXs’ capabilities.

We often check the dashboard which shows the maintenance requirements for each machine in one place, and helps us schedule and conduct the needed maintenance procedures. Also, the status for each machine is color-coded, which helps us instantly see whether milling has been completed and check the current condition of each machine at a glance.

We have five DWX series milling machines. To maximize our uptime, we manage the data input timing so that machine downtimes do not overlap. The ideal timing is after one machine finishes maintenance operations and starts with new data input, the next machine stops for its maintenance operations.

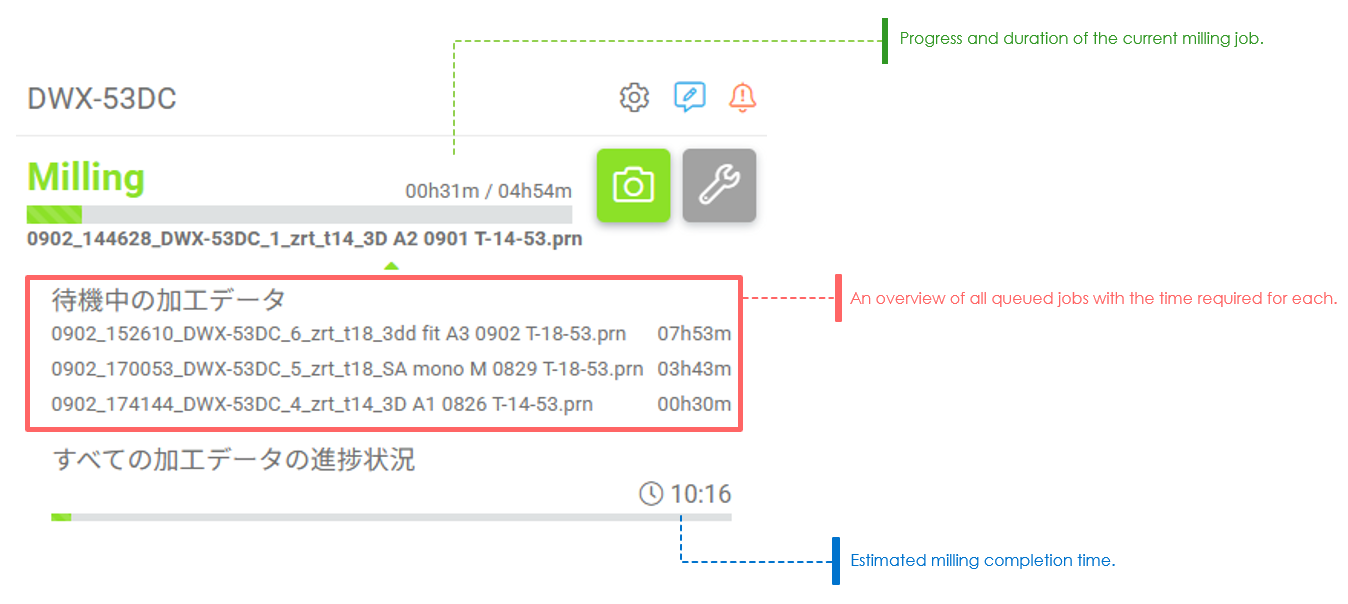

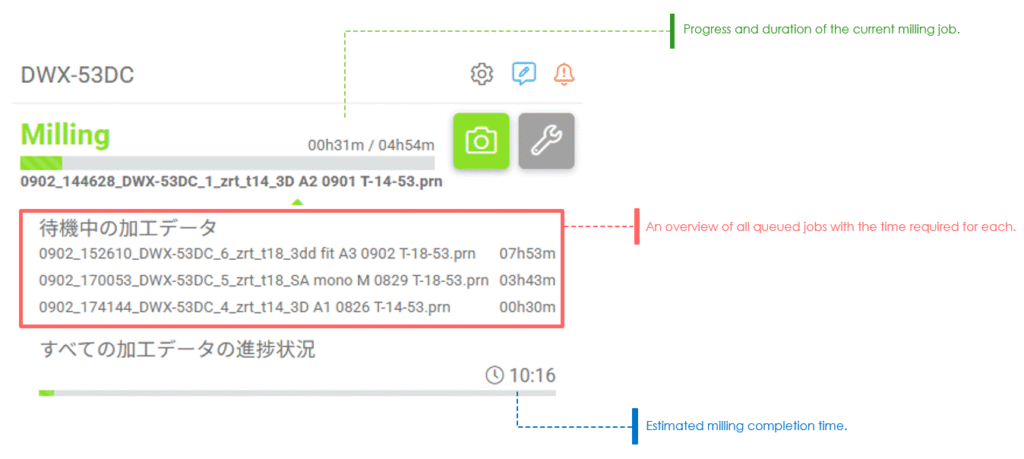

We can check the progress and duration of the current milling job, as well as the estimated time required for pending jobs, through DGSHAPE Insight. We use this information to prepare the additional job data.

We have five DWX series milling machines. To maximize our uptime, we manage the data input timing so that machine downtimes do not overlap. The ideal timing is after one machine finishes maintenance operations and starts with new data input, the next machine stops for its maintenance operations.

We can check the progress and duration of the current milling job, as well as the estimated time required for pending jobs, through DGSHAPE Insight. We use this information to prepare the additional job data.

DGSHAPE Insights leads ‘Data-driven decision making’

DGSHAPE Insights leads ‘Data-driven decision making’

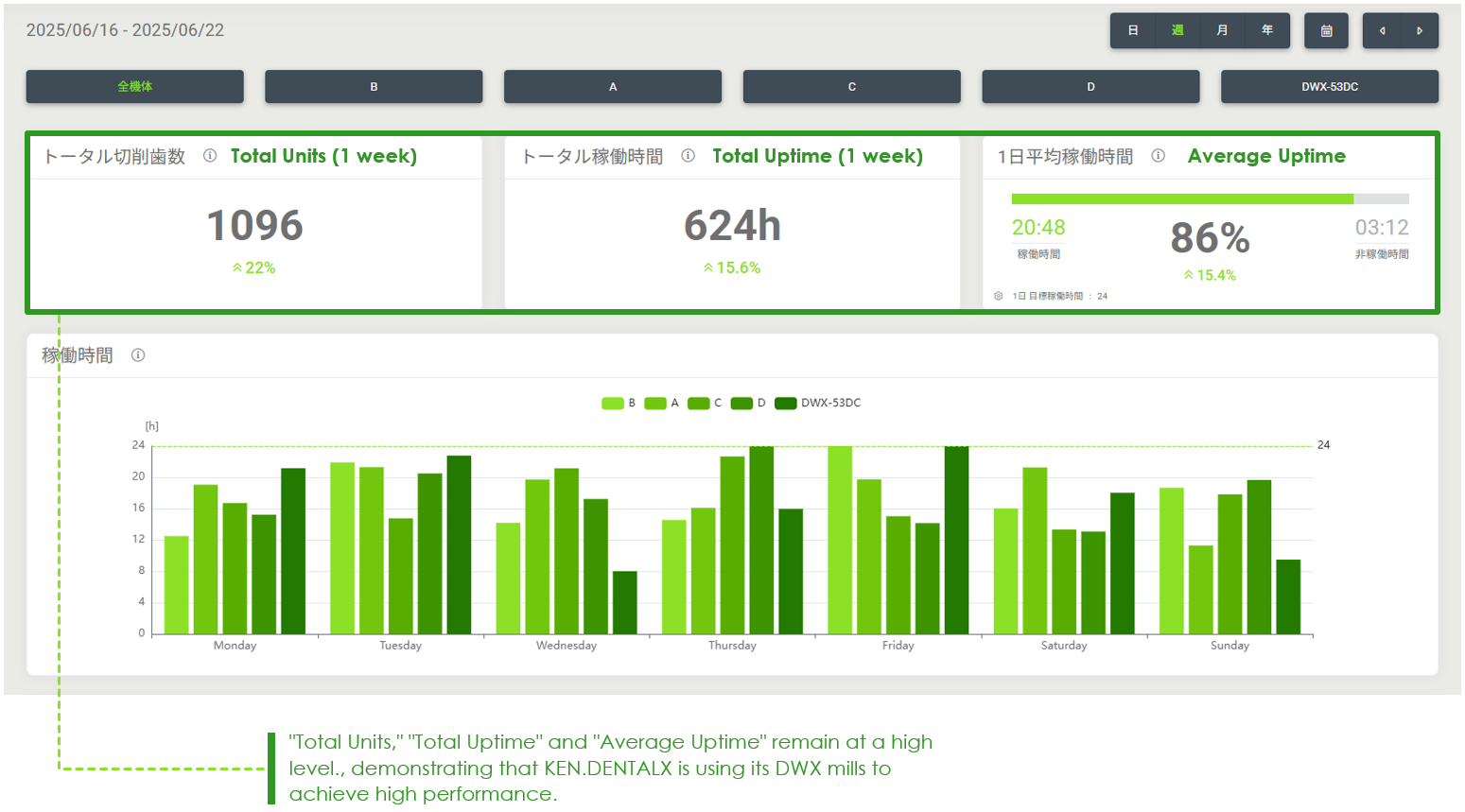

We can check various kinds of numerical data, such as “Total units,” Total Uptime,” and “Average Uptime” on the Machine History page. Milling machine operators share this data with the management sector staff every month. Once the data are shared, we analyze the data trends. We compare the data to the number of orders and estimate whether we can complete them with the current number of milling machines, or whether we should install new milling machines. If new machines are needed, we calculate how much our sales and profit would increase, etc. Using the data from DGSHAPE Insights, we can simulate several possible outcomes.

We believe we can use these data to not only optimize the milling process, but also optimize all lab workflows. For instance, when total units and uptime keep increasing, we can consider installing new machines to produce more units. However, we can also consider whether there is a workload backup at the CAD design stage. In this case, installing new milling machines would not be a practical solution. Thus, by examining the data from DGSHAPE Insights, we can evaluate various solutions to improve lab efficiency.

We can check various kinds of numerical data, such as “Total units,” Total Uptime,” and “Average Uptime” on the Machine History page. Milling machine operators share this data with the management sector staff every month. Once the data are shared, we analyze the data trends. We compare the data to the number of orders and estimate whether we can complete them with the current number of milling machines, or whether we should install new milling machines. If new machines are needed, we calculate how much our sales and profit would increase, etc. Using the data from DGSHAPE Insights, we can simulate several possible outcomes.

We believe we can use these data to not only optimize the milling process, but also optimize all lab workflows. For instance, when total units and uptime keep increasing, we can consider installing new machines to produce more units. However, we can also consider whether there is a workload backup at the CAD design stage. In this case, installing new milling machines would not be a practical solution. Thus, by examining the data from DGSHAPE Insights, we can evaluate various solutions to improve lab efficiency.

Expectation for DGSHAPE Insights

Expectation for DGSHAPE Insights

DGSHAPE Insights is already a convenient tool, however it has the potential to be even more effective with further development. We hope DGSHAPE Insights will continue its evolution.

DGSHAPE Insights is already a convenient tool, however it has the potential to be even more effective with further development. We hope DGSHAPE Insights will continue its evolution.

Creating a DGSHAPE Account (Free) and Get Started

Creating a DGSHAPE Account (Free) and Get Started

By creating a DGSHAPE Account you can access the DGSHAPE CLOUD, a cloud service that enables comprehensive, mobile management for your DWX milling devices thanks to its web-app: DGSHAPE Insights.

By creating a DGSHAPE Account you can access the DGSHAPE CLOUD, a cloud service that enables comprehensive, mobile management for your DWX milling devices thanks to its web-app: DGSHAPE Insights.

After creating your DGSHAPE Account, you can access the free DGSHAPE Insights.

After creating your DGSHAPE Account, you can access the free DGSHAPE Insights.