① Tell us about Dental Lab Academy by Dahmen & Asma

① Tell us about Dental Lab Academy by Dahmen & Asma

Dental Lab Academy by Dahmen & Asma is a modern dental technology laboratory based in Tunisia, founded by two passionate dental technicians, Dahmen and Asma. Both graduates from Centrale University of Tunisia (Class of 2020), we bring together over five years of experience in crafting high‑quality dental prosthetics. Our laboratory specializes in the design and fabrication of crowns, bridges, dentures, implants, and orthodontic appliances, combining speed and precision to meet the highest standards of dentistry. Using the latest CAD/CAM technologies, 3D printing, and digital scanning, we ensure natural aesthetics, perfect fit, and long‑lasting results. We work closely with dentists and clinics to deliver solutions that restore smiles with comfort and confidence — because at Dental Lab Academy, every smile matters.

Dental Lab Academy by Dahmen & Asma is a modern dental technology laboratory based in Tunisia, founded by two passionate dental technicians, Dahmen and Asma. Both graduates from Centrale University of Tunisia (Class of 2020), we bring together over five years of experience in crafting high‑quality dental prosthetics. Our laboratory specializes in the design and fabrication of crowns, bridges, dentures, implants, and orthodontic appliances, combining speed and precision to meet the highest standards of dentistry. Using the latest CAD/CAM technologies, 3D printing, and digital scanning, we ensure natural aesthetics, perfect fit, and long‑lasting results. We work closely with dentists and clinics to deliver solutions that restore smiles with comfort and confidence — because at Dental Lab Academy, every smile matters.

② When and how did you become aware of DGSHAPE Insights, the software developed for DWX users?

② When and how did you become aware of DGSHAPE Insights, the software developed for DWX users?

We began using DGSHAPE Insights in October 2024, shortly after acquiring our first DWX-52Di machine. At that time, we had a long milling job that required nearly six hours to complete. It was difficult to stay in the lab for such an extended period, but I couldn‘t leave the machine because I was worried an error might occur during the process. That’s when our reseller introduced us to DGSHAPE Insights, explaining that we could monitor the machine status and milling progress remotely through our smartphone or other electronic devices. From that moment, it became an essential part of our daily operations.

We began using DGSHAPE Insights in October 2024, shortly after acquiring our first DWX-52Di machine. At that time, we had a long milling job that required nearly six hours to complete. It was difficult to stay in the lab for such an extended period, but I couldn‘t leave the machine because I was worried an error might occur during the process. That’s when our reseller introduced us to DGSHAPE Insights, explaining that we could monitor the machine status and milling progress remotely through our smartphone or other electronic devices. From that moment, it became an essential part of our daily operations.

③ What are the key features of DGSHAPE Insights that you use most frequently?

③ What are the key features of DGSHAPE Insights that you use most frequently?

- Machine History

- Machine Status

- Dashboard

- Machine History

- Machine Status

- Dashboard

④ How “Machine History” Gave Our New Lab the Clarity to Grow

④ How “Machine History” Gave Our New Lab the Clarity to Grow

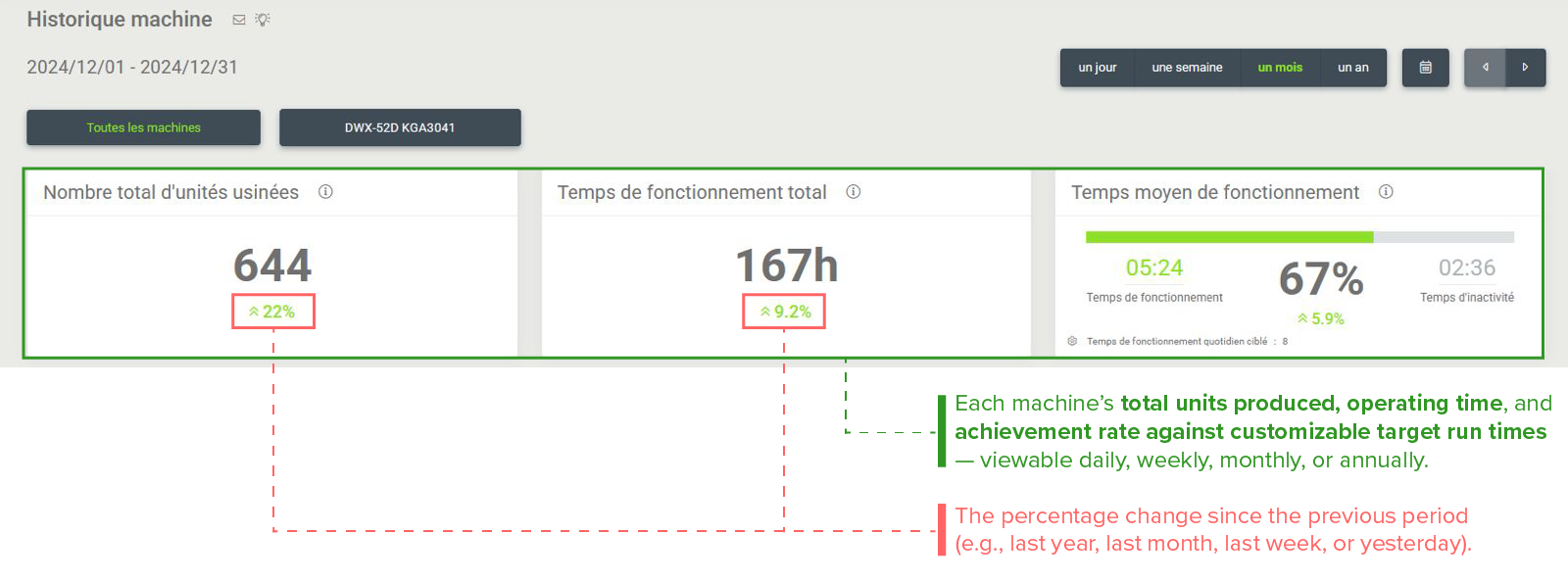

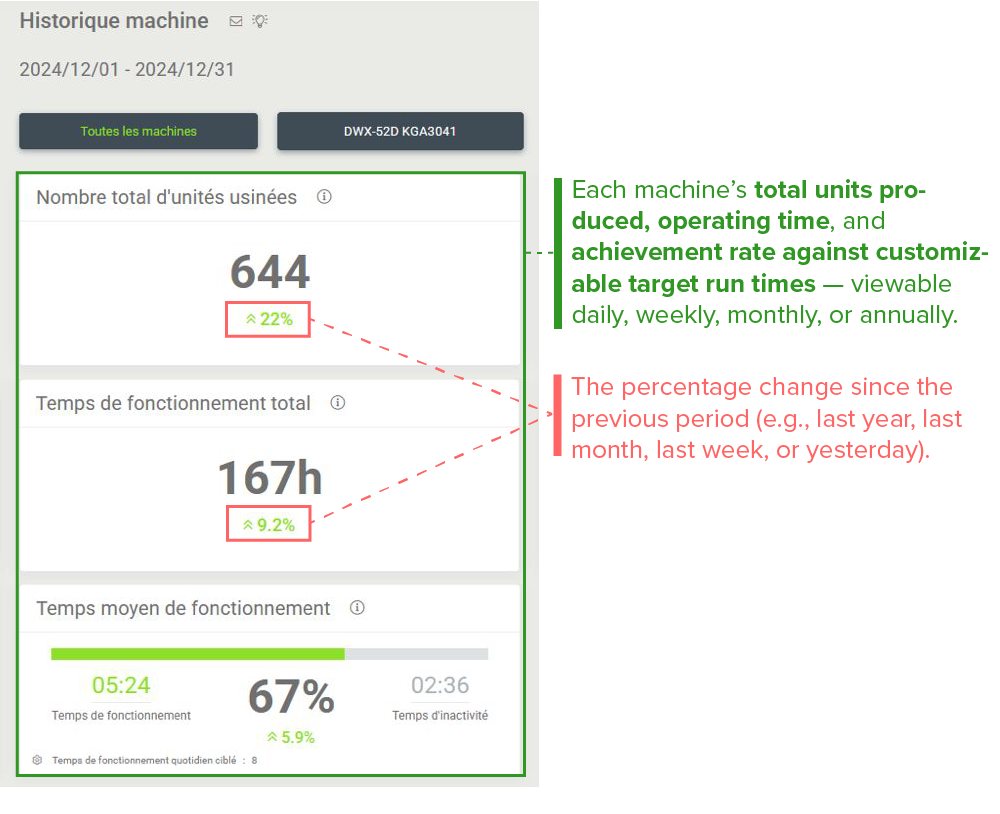

Machine History is my favorite feature. It provides detailed data on the number of units milled, milling time, and even the type of restorations produced — daily, weekly, monthly, or annually. This helps me track our production targets and analyze trends.

As a new lab, we’ve clearly defined monthly production and sales targets to cover ongoing costs—such as materials, labor, and office rent—while still aiming for sustainable growth. Machine History lets us see exactly how many units we’ve produced each month and whether we’re on track, making it easier to set goals and identify what improvements are needed for the next month. Since the data is easy to share with the team, it also helps keep everyone aligned and focused on hitting our targets.

Machine History is my favorite feature. It provides detailed data on the number of units milled, milling time, and even the type of restorations produced — daily, weekly, monthly, or annually. This helps me track our production targets and analyze trends.

As a new lab, we’ve clearly defined monthly production and sales targets to cover ongoing costs—such as materials, labor, and office rent—while still aiming for sustainable growth. Machine History lets us see exactly how many units we’ve produced each month and whether we’re on track, making it easier to set goals and identify what improvements are needed for the next month. Since the data is easy to share with the team, it also helps keep everyone aligned and focused on hitting our targets.

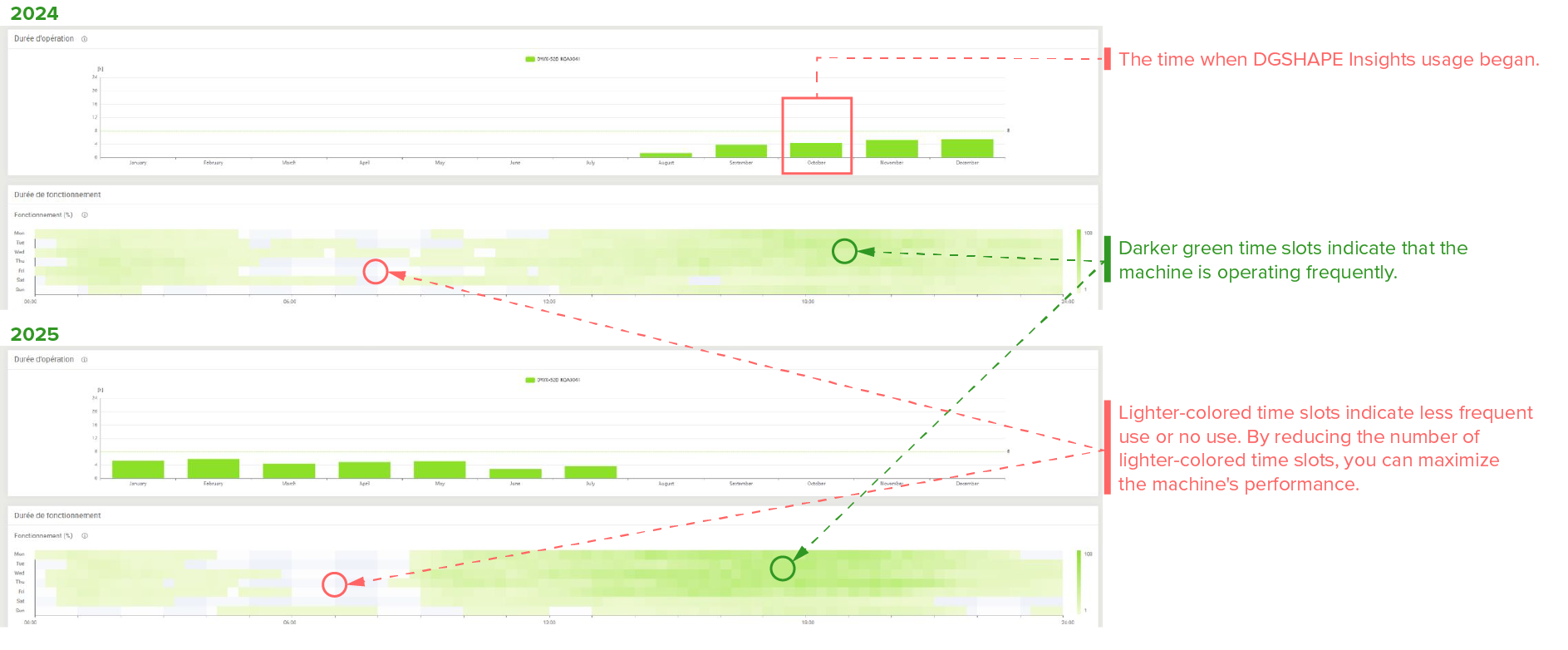

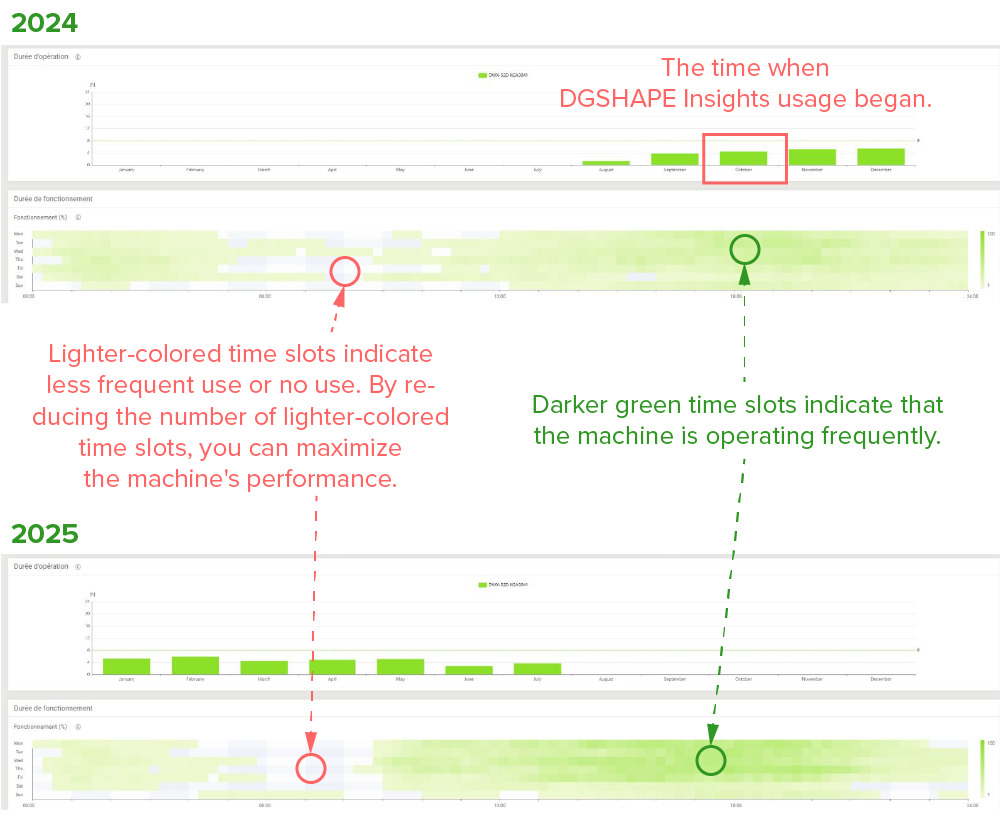

The bar chart below illustrates our actual monthly operating hours for our DWX in 2024 (on the left) and 2025 (on the right). The heatmap beneath it shows when DWX was in operation, classified by day of the week and time of day. We began using DGSHAPE Insights in October 2024. Thanks to its support, we’ve seen a steady increase in uptime and have been able to maintain a high level of uptime. The heatmap data shows that our DWX is now utilized consistently across all days and times, except for the early hours of the morning, reflecting a well-balanced and efficient operation.

By visualizing our operating patterns, DGSHAPE Insights’ Machine History helps us understand and improve how we work.

The bar chart below illustrates our actual monthly operating hours for our DWX in 2024 (on the left) and 2025 (on the right). The heatmap beneath it shows when DWX was in operation, classified by day of the week and time of day. We began using DGSHAPE Insights in October 2024. Thanks to its support, we’ve seen a steady increase in uptime and have been able to maintain a high level of uptime. The heatmap data shows that our DWX is now utilized consistently across all days and times, except for the early hours of the morning, reflecting a well-balanced and efficient operation.

By visualizing our operating patterns, DGSHAPE Insights’ Machine History helps us understand and improve how we work.

⑤ Fewer Trips, Deeper Focus: How “Machine Status” Transformed My Work Style

⑤ Fewer Trips, Deeper Focus: How “Machine Status” Transformed My Work Style

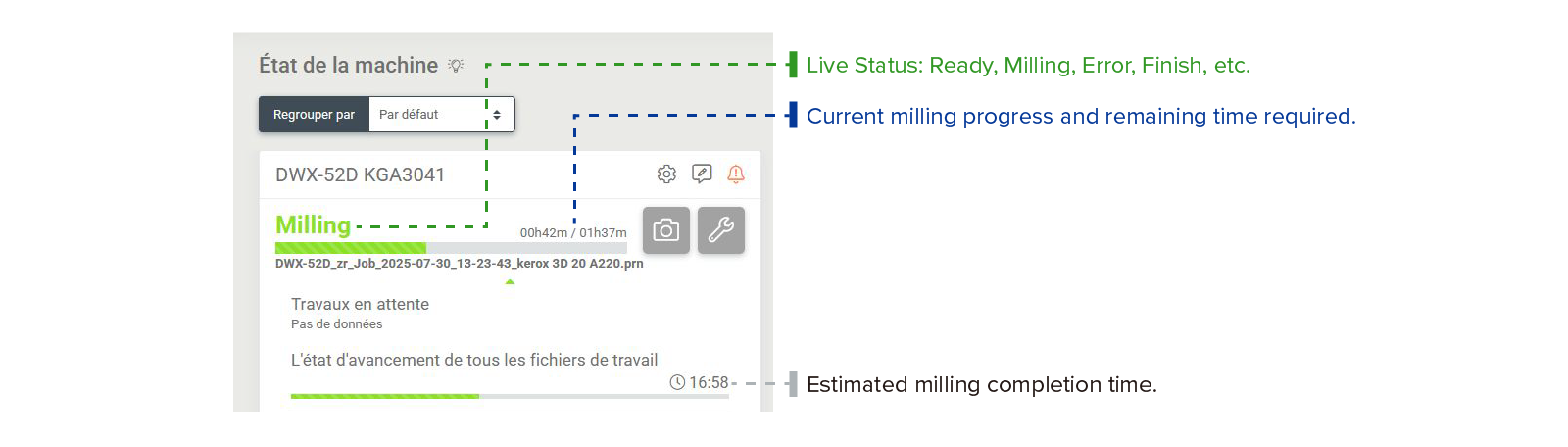

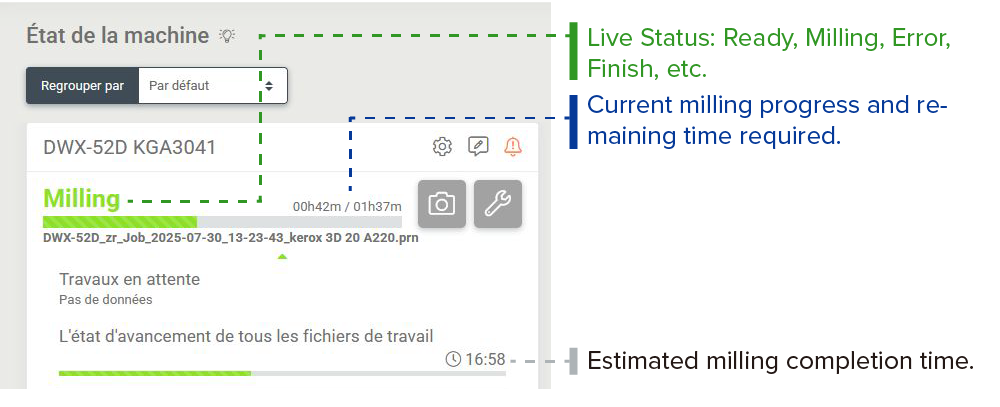

Machine Status has become an essential part of our remote work. Since my lab and home are only about a 15-minute drive apart, and my house offers a more comfortable environment, I often design restorations and other focus-intensive tasks from home. After starting a milling job at the lab, I return home and continue working on different tasks while checking the milling progress and any error notifications on my smartphone. It tells me exactly how much milling time remains, helping me plan the return to the lab efficiently. This flexibility saves our lab a great deal of time and enables a more productive work style.

Machine Status has become an essential part of our remote work. Since my lab and home are only about a 15-minute drive apart, and my house offers a more comfortable environment, I often design restorations and other focus-intensive tasks from home. After starting a milling job at the lab, I return home and continue working on different tasks while checking the milling progress and any error notifications on my smartphone. It tells me exactly how much milling time remains, helping me plan the return to the lab efficiently. This flexibility saves our lab a great deal of time and enables a more productive work style.

⑥ Keeping Our Growing Lab Running: How “Dashboard” Supports Maintenance and Quality

⑥ Keeping Our Growing Lab Running: How “Dashboard” Supports Maintenance and Quality

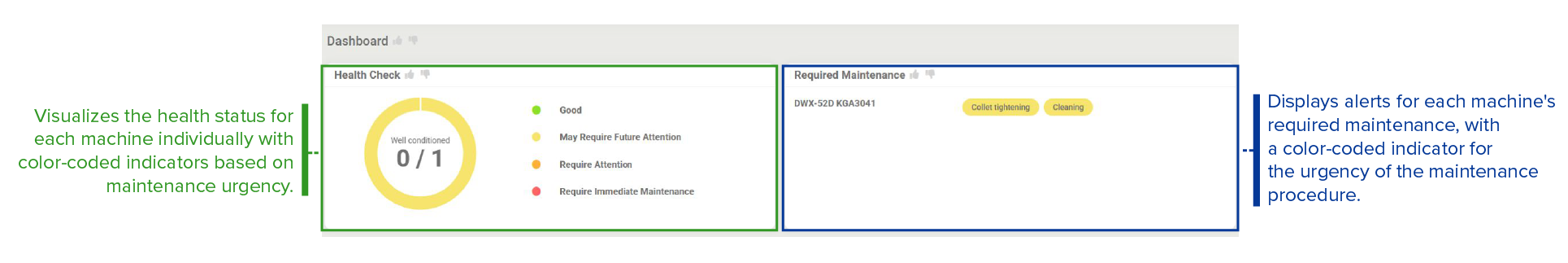

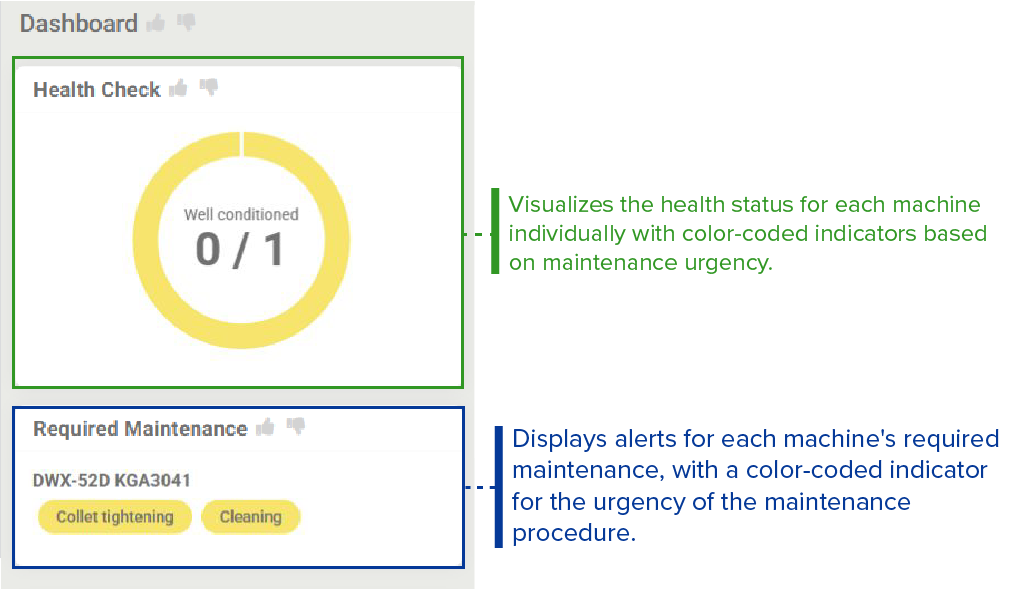

For us, Dashboard is an essential tool for monitoring the health of our machine. It provides us with timely insights into the machine’s maintenance needs, enabling us to plan maintenance proactively and avoid downtime and unexpected issues that could delay production. Especially for a small but growing lab like ours, minimizing disruptions is key to maintaining high service quality for our clients.

For us, Dashboard is an essential tool for monitoring the health of our machine. It provides us with timely insights into the machine’s maintenance needs, enabling us to plan maintenance proactively and avoid downtime and unexpected issues that could delay production. Especially for a small but growing lab like ours, minimizing disruptions is key to maintaining high service quality for our clients.

⑦ Message for DWX Users

⑦ Message for DWX Users

I definitely recommend DGSHAPE Insights to all DWX users.

First of all, it helps you monitor your machine’s health at all times—you can always check if it needs any attention. Also, you can see the machine status anytime, even from your mobile phone—whether it’s working or not, and what it’s doing. One of my favorite features is Machine History. It tells you exactly how many units have been produced and how long the machine has been operating. You can even compare that data with data from previous months or years. So, I highly recommend it. It’s very useful, and I hope the platform continues to improve with new features and updates.

I definitely recommend DGSHAPE Insights to all DWX users.

First of all, it helps you monitor your machine’s health at all times—you can always check if it needs any attention. Also, you can see the machine status anytime, even from your mobile phone—whether it’s working or not, and what it’s doing. One of my favorite features is Machine History. It tells you exactly how many units have been produced and how long the machine has been operating. You can even compare that data with data from previous months or years. So, I highly recommend it. It’s very useful, and I hope the platform continues to improve with new features and updates.

Creating a DGSHAPE Account (Free) and Get Started

Creating a DGSHAPE Account (Free) and Get Started

By creating a DGSHAPE Account you can access the DGSHAPE CLOUD, a cloud service that enables comprehensive, mobile management for your DWX milling devices thanks to its web-app: DGSHAPE Insights.

By creating a DGSHAPE Account you can access the DGSHAPE CLOUD, a cloud service that enables comprehensive, mobile management for your DWX milling devices thanks to its web-app: DGSHAPE Insights.

After creating your DGSHAPE Account, you can access the free DGSHAPE Insights.

After creating your DGSHAPE Account, you can access the free DGSHAPE Insights.