Advantages of Choosing the DWX-43W

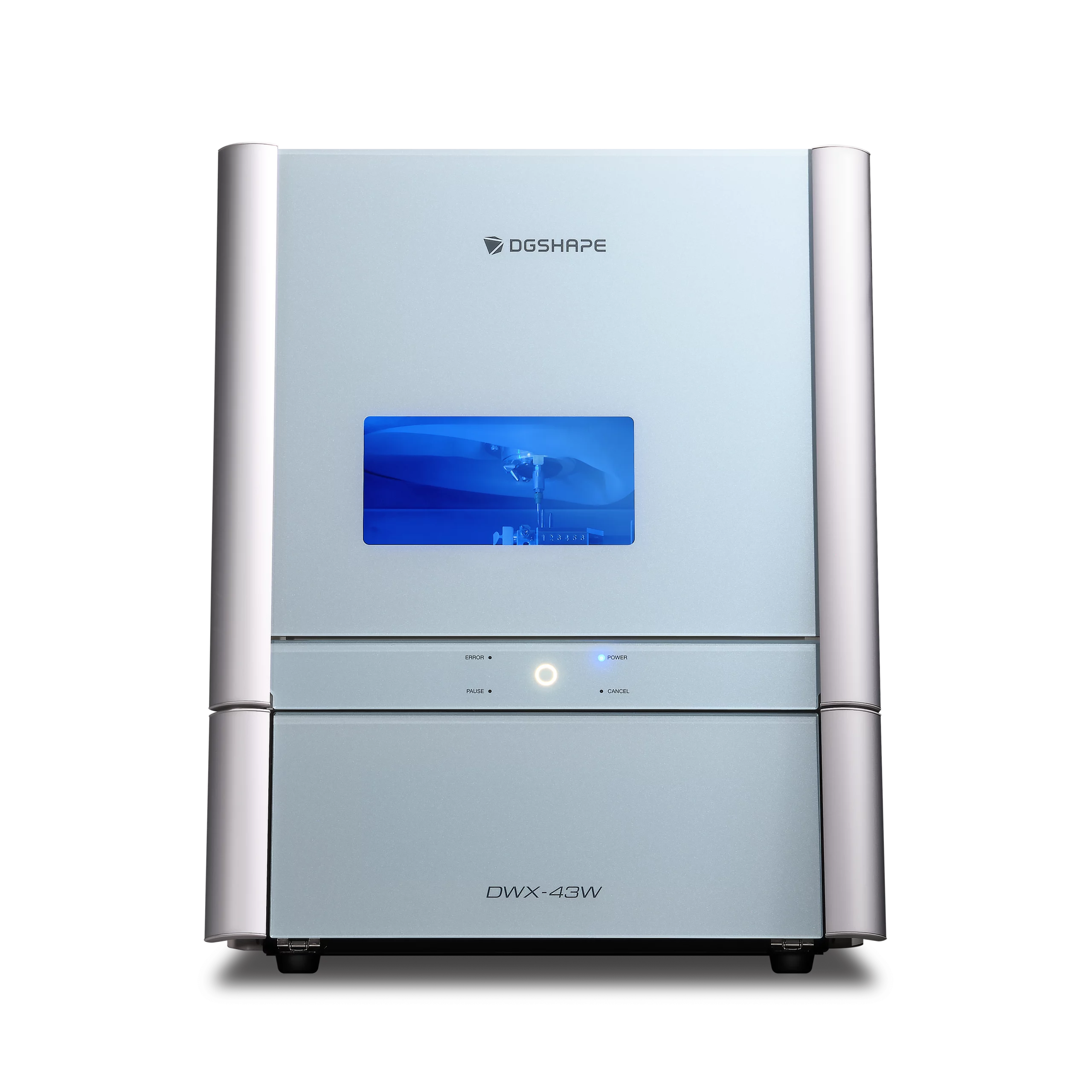

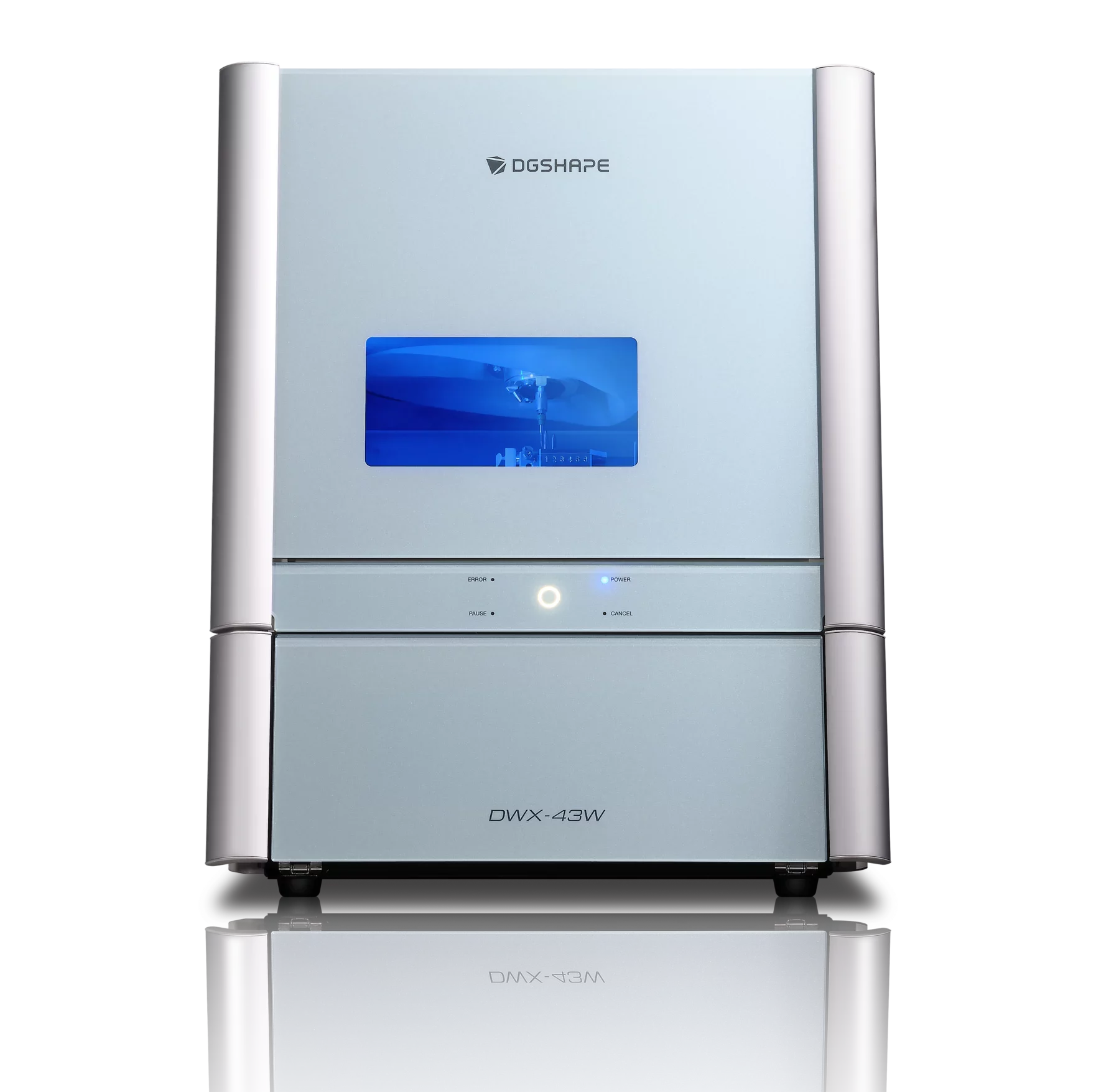

Boost your productivity and precision with the DWX-43W, the new versatile wet milling solution from industry leader DGSHAPE.

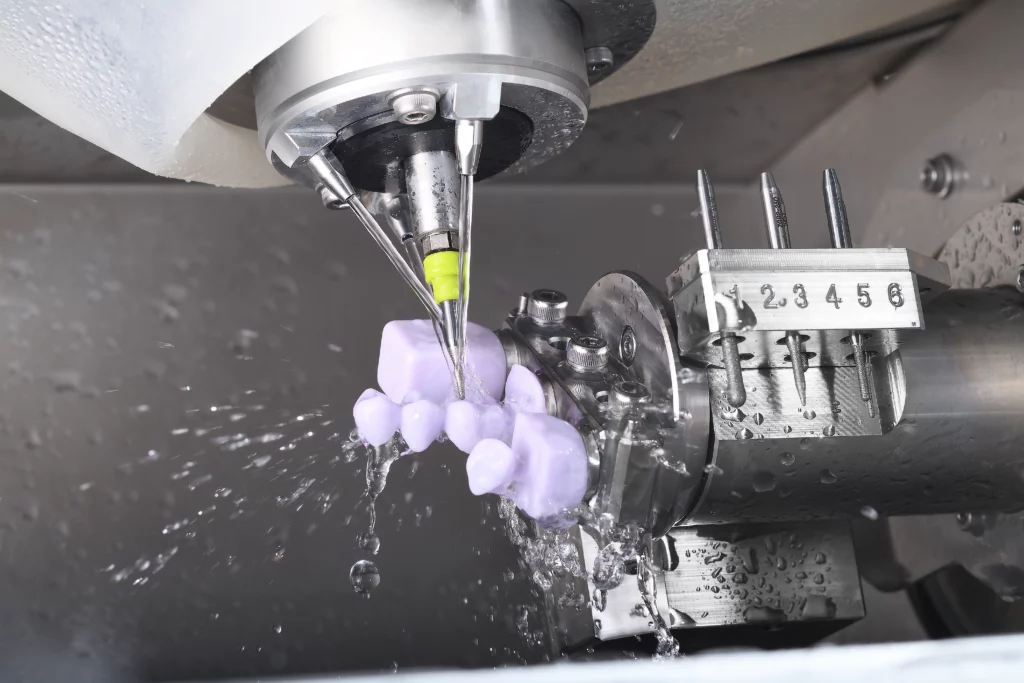

The DWX-43W can simultaneously mill up to six pin-type blocks with unparalleled accuracy.

Compatible with a wide range of materials, including sintered zirconia, glass ceramics, hybrid ceramics, PEEK, composite resins, PMMA, and titanium alloy*, it’s designed to meet all your in-house production needs.

From crowns and veneers to custom titanium abutments (with optional attachments), the DWX-43W ensures consistent, high-quality results while streamlining workflows with automated maintenance and user-friendly software.

Experience faster, smarter, and more versatile milling with the DWX-43W – the perfect blend of precision, performance, and affordability.

*Optional attachment required for titanium alloy milling.

DGSHAPE CAM Software Included

Mill Up to 6 Pin-Type Blocks

Efficient Operation

Mill Titanium (only pre-milled abutments)

*The optional attachment and milling burs are required.

Easy to Use

Remote Monitor

Millable Materials

- Glass ceramics

- Composite resin

- Hybrid ceramics

- PMMA

- Sintered Zirconia

- Titanium (Titanium custom abutments can be milled from pre-milled titanium blanks using optional AK-1)

Millable Material

Discover the Variety of Materials You Can Mill with Your New DWX-43W

- Glass ceramics

- Composite Resin

- Hybrid ceramics

- PMMA

- Sintered Zirconia

- Titanium (Titanium custom abutments can be milled from pre-milled titanium blanks using optional attachment and ZTR/ZTB milling burs)

Millable Applications

Discover the Range of Applications You Can Create with Your DWX-43W

Whether you’re crafting dental crowns, bridges, or custom abutments, this advanced technology ensures exceptional quality and consistency in every piece.

With the DWX-43W, you can explore a wide range of dental applications, all produced with the highest standards of accuracy and detail.

Inlay

Onlay

Overlay

Crown

Bridge

Veneer

Abutments

The DWX-43W is the ideal machine for those focusing on digital dentistry and high-quality aesthetics.

I already had the previous model, but this one represents a true leap forward: the absence of filters means less maintenance, lower operating costs, and improved overall profitability.

It is an extremely versatile machine, capable of efficiently handling materials .

The intuitive software simplifies the entire process, and the ability to mill up to six blocks simultaneously is a great advantage in terms of productivity.

Dr. Paolo Avantaggiato

Highlights

Versatile Performer for In-House Production

The DWX-43W brings outstanding versatility, precision, and range to your wet milled production.

The DWX-43W mills a wide variety of materials, including sintered zirconia, glass ceramics, composite resins, hybrid-ceramics, and PMMA, consistently and accurately producing small-bridges, single crowns, screw-retained crowns, veneers, inlays, onlays, and copings. Add easy in-house production of custom titanium abutments with dedicated Attachments (sold separately).

Consistent Accuracy Assures Quality

With DGSHAPE genuine grinding burs (ZGB/ZGB2 series) and the bundled DGSHAPE CAM, the DWX-43W offers consistent, precise milling of dental applications. In addition, its stabilized frame enables high-quality milling of custom titanium abutments.

Automated Maintenance Features Save Time

Save valuable time with the DWX-43W’s automated maintenance features.

Auto-rinse prevents contamination, sticking, and drying, maintaining clean and efficient production.

Automatic correction ensures accurate milling while saving hours of manual calibration.

With an improved waterflow system, milling burs and other device parts stay cleaner for longer with no need for costly filter consumables.

Faster Milled Production

The included multi-pin clamp accessory saves you time, allowing you to add up to six units simultaneously and batch mill – without compromising quality.

Versatile Performer for In-House Production

The DWX-43W brings outstanding versatility, precision, and range to your wet milled production.

The DWX-43W mills a wide variety of materials, including sintered zirconia, glass ceramics, composite resins, hybrid-ceramics, and PMMA, consistently and accurately producing small-bridges, single crowns, screw-retained crowns, veneers, inlays, onlays, and copings. Add easy in-house production of custom titanium abutments with dedicated Attachments (sold separately).

Consistent Accuracy Assures Quality

With DGSHAPE genuine grinding burs (ZGB/ZGB2 series) and the bundled DGSHAPE CAM, the DWX-43W offers consistent, precise milling of dental applications. In addition, its stabilized frame enables high-quality milling of custom titanium abutments.

Automated Maintenance Features Save Time

Save valuable time with the DWX-43W’s automated maintenance features.

Auto-rinse prevents contamination, sticking, and drying, maintaining clean and efficient production.

Automatic correction ensures accurate milling while saving hours of manual calibration.

With an improved waterflow system, milling burs and other device parts stay cleaner for longer with no need for costly filter consumables.

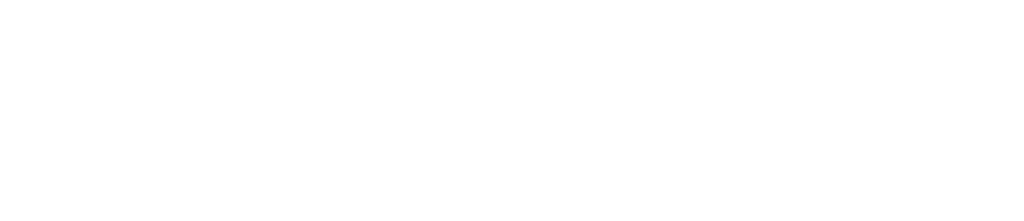

In addition, the included Virtual Panel software (VPanel for DWX) seamlessly provides maintenance oversight and output performance control.

Faster Milled Production

The included multi-pin clamp accessory saves you time, allowing you to add up to six units simultaneously and batch mill – without compromising quality.

Optimize Your Workflow with Bundled DGSHAPE CAM for DWX-43W

Included DGSHAPE CAM Software enables you to select either High-Quality (Standard) or Fast Strategy production according to your needs.

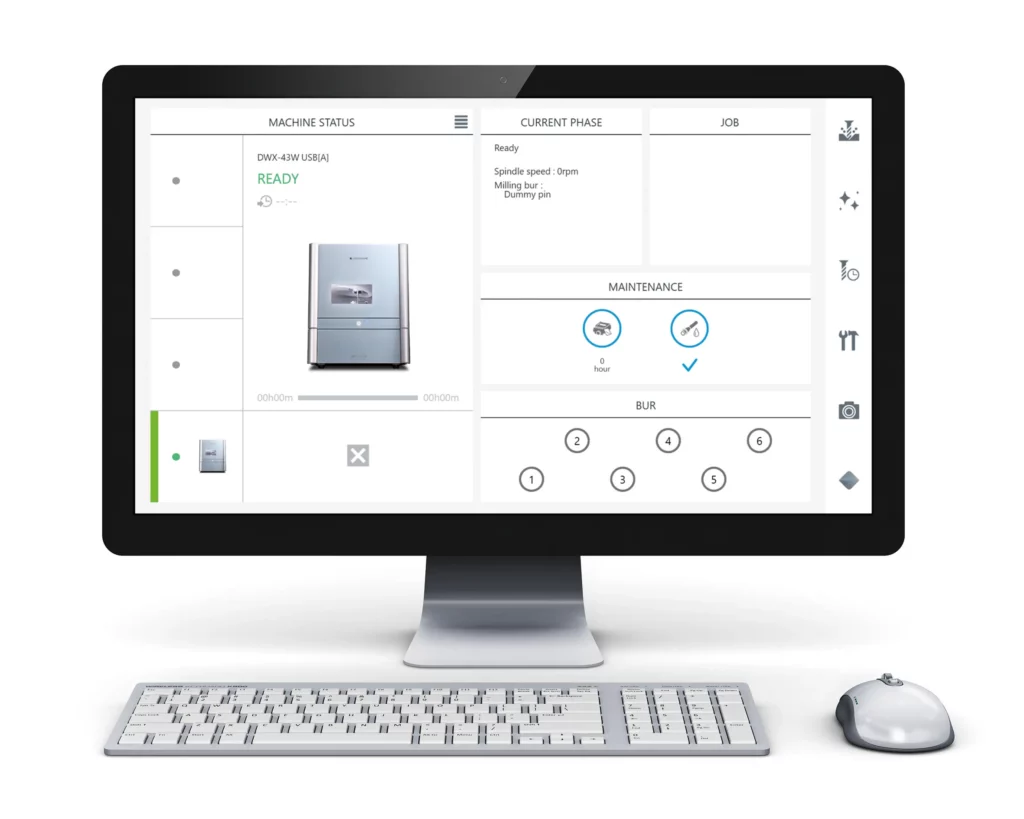

In addition, DGSHAPE CAM is fully integrated with DGSHAPE Insights, enabling DGSHAPE Insights to display more detailed information, such as the number of outputs and materials used, and to provide deeper insights to improve your operations efficiency.

The ZGB Strategy is used for milling materials with relatively high hardness, such as sintered zirconia and crystalized glass ceramics, while the ZGB2 Strategy is used for milling materials such as pre-crystalized glass ceramics, hybrid resins, and other materials.

You can download it from Roland DG Download Center.

The warranty for the DGSHAPE CAM for DWX-43W provided directly by DGSHAPE lasts for two years. The dealer from whom the customer purchases the CAM may offer any warranty extensions. Additionally, DGSHAPE provides a customer support subscription service.

Please inquire of your resellers.

Only DWX-43W model is compatible with the DGSHAPE CAM for DWX-43W.

In addition, DGSHAPE has direct subsidiaries in the main countries where it operates, ensuring comprehensive support in the local language.

| Component | Minimum Requirement | Suggested Requirement |

|---|---|---|

| Operating System (OS) | Windows 11 (64bit) | Windows 11 (64bit) |

| CPU | Intel 64bit or AMD 64bit Processor | Intel i9 64bit or AMD Ryzen 9 64bit |

| Memory | 16 GB or more | 32 GB |

| Video Card | Nvidia RTX/GTX 4GB RAM | Nvidia RTX 4 GB |

| Hard Disk | 500GB or more | 1 TB |

| Interface | USB (For USB License Key – Dongle) | – |

VPanel for DWX

With VPanel you can control your milling machine.

Monitor tool use and set notifications so you know when milling jobs are done, operations are completed, or when an error has occurred, so you can save time for other jobs.

VPanel has a very user friendly interface, that allows you to use it in the best way.

Fully leverage your experience with DGSHAPE through DGSHAPE CLOUD, an advanced cloud service provided by DGSHAPE.

Accessible via your DGSHAPE Account, it grants you access to Insights, a tool for remotely monitoring your CAD/CAM milling devices and supporting your business.

Technical information

61 kg (134.5 lbs.)

Width 482 mm (19 in.) x Depth 560 mm (22 in.) x Height 600 mm (23.6 in.)

Pin-type

Max. 40 mm (1.5 in.)(Width) x 20 mm (0.8 in.)(Depth) x 20 mm (0.8 in.)(Height)

Operating speed: XYZ axis 6 to 1,800 mm/min (0.24 to 70.9 in/min)

Spindle rotating speed: 15,000 to 60,000 rpm

Rotary axis travel angle: A ±360°

Up to 6 pieces

Shank diameter: 3 mm (0.12 in.)

Interface: USB or Ethernet (10 BASE-T/100 BASE TX automatic switching)

Power requirements: AC 100 V to 240 V ±10%, 50/60 Hz (overvoltage category II, IEC60664-1), 2.1 A

Power consumption: approx. 190 W

ZGB2-125D φ2.5mm grinding bur

ZGB2-75D φ1.5mm grinding bur

ZGB2-50D φ1mm grinding bur

ZGB2-25D φ0.5mm grinding bur

ZGB-125D φ2.5mm grinding bur

ZGB-50D φ1mm grinding bur

ZGB2-125DS φ2.5mm grinding bur for optional strategy

ZTR-150D φ3mm milling bur for titanium alloy

ZTB-100D φ2mm milling bur for titanium alloy and PEEK

ZTB-50D φ1mm milling bur for titanium alloy and PEEK

ZV-42W Multi pin Clamp

ZC-3D Collet

ZAW-1000D Coolant Additive

ZCH-250D Chelating Additive

AK-1-DE/GE/ME/NT Attachment for titanium custom abutment

Frequently Asked Questions

Mainly for three reasons: the quality of the machinery, our milling machines have a very long lifecycle; the quality of the produced applications, the lifecycle of the tools and ease of use.

Our decision to separate dry from wet milling production stems from the idea of providing our customers with dental milling machines that are easy to use, require little maintenance, and have the fewest possible issues during their lifecycle.

The warranty for DWX models provided directly by DGSHAPE lasts for one year.

The dealer from whom the customer purchases the machine may offer any warranty extensions. Additionally, DGSHAPE provides a customer support subscription service.

One of the strengths of DGSHAPE dental milling machines is their ease of use, from calibration to maintenance.

We at DGSHAPE do not directly provide courses, but usually, it’s our trained dealers who offer assistance and courses from the initial installation.

Finally, we have tutorials on our website and YouTube channel.

Through our network of dealers, we are present in over 200 countries.

In addition, DGSHAPE has direct subsidiaries in the main countries where it operates, ensuring comprehensive support in the local language.

We firmly believe in the quality of our machinery, which is why DGSHAPE provides spare parts for its dental milling machines at a reasonable cost.

Additionally, it allows for easy replacement of the spindle, which can be done autonomously by the machine owner.

Contact Us

Demo

Would you like to request a free demo?

Fill out our form to discover the best

solution for your business.

Quote

Are you interested in one of our dental milling machines?

Fill out the form and we’ll send you a quote.

Consultation

Do you want to speak with our experts?

Fill out the form and we’ll contact you as soon as possible.

Our DGSHAPE authorized dealers are carefully selected, and offer superior expertise and tailored advice across a range of DGSHAPE products and services

By filling out the form, we ensure

- Quick dealer contact

- Expert dealer matching for your country

- Time-saving dealer search

- Authentic DGSHAPE products and services

DGSHAPE A Roland DG Group Company

Roland DG Group Company has been the benchmark for advanced machine manufacturing for over 38 years, thanks to its practical and reliable technology with unmatched support.

DGSHAPE continues and enhances this legacy, making it easier and more effective for laboratories and clinics to produce high-quality, cost-effective dental prosthetics.