DGSHAPE Make Innovation Make Life Better

Corporate History

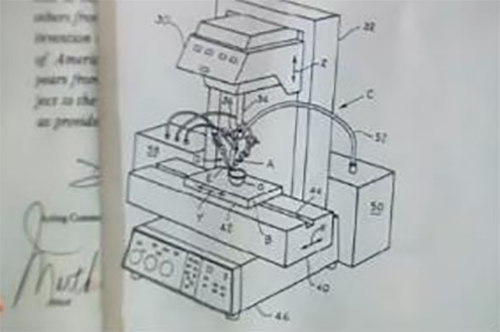

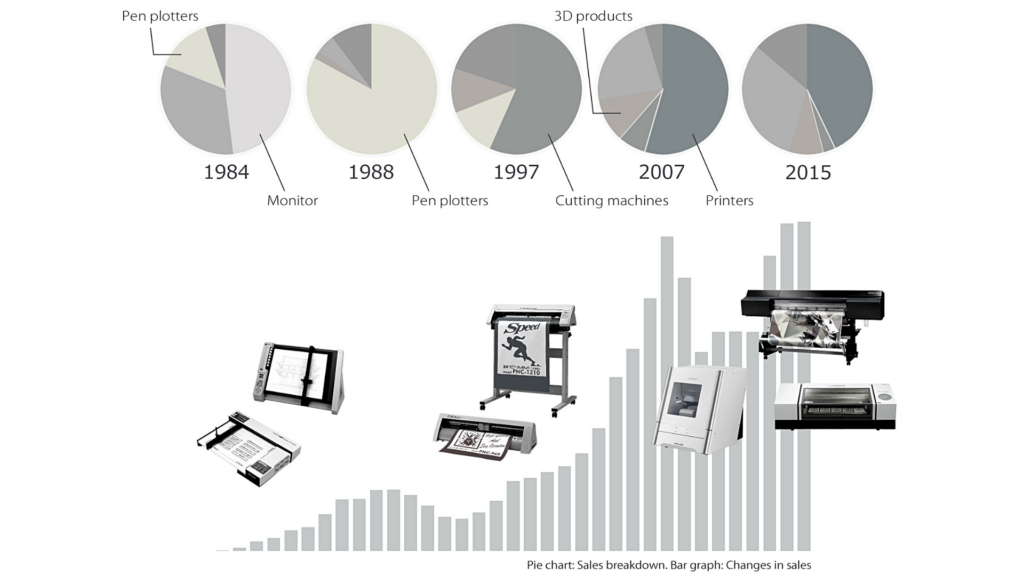

Since the founding of our company, we have pioneered new manufacturing processes based on unique digital technologies that control the XYZ axes or lateral, longitudinal, and vertical movement. Originally applied to the development of pen plotters for designing and drafting applications, our product line soon evolved to include cutting plotters which replaced the pen with a cutter. Both of these product lines were based on our control technology for the XY axes. The Roland DG line of output devices eventually grew to include color printers equipped with inkjet heads and cutters, and 3D milling machines that controlled the XY and Z axes.

Today, our main line-up of products consists of wide-format inkjet printers that support a variety of industries including the sign industry and machine tools such as milling machines and engraving devices designed to streamline manufacturing processes.

Our core technology

Technology for controlling lateral (X axis), longitudinal (Y axis), and vertical (Z axis) positions.

Globally expanding sales network

Through a network of sales subsidiaries and dealers, the Company’s products and services now reach 200 countries and regions around the world. Marketing and sales activities tailored to local culture and customs are headed up by a team of regional staff members to ensure a proper fit for the market tand its customers.

Register your DWX quickly and easily

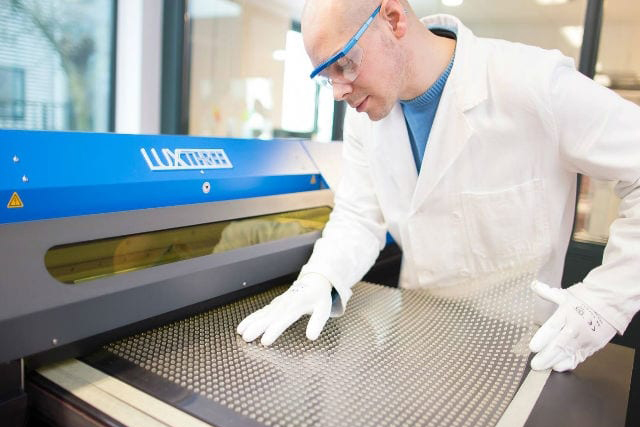

“D-shop”: Our proprietary production system

The products we develop are produced in individual “D-shops” a cell-based production system whereby one person works in each cell.

Outline of Dental Business

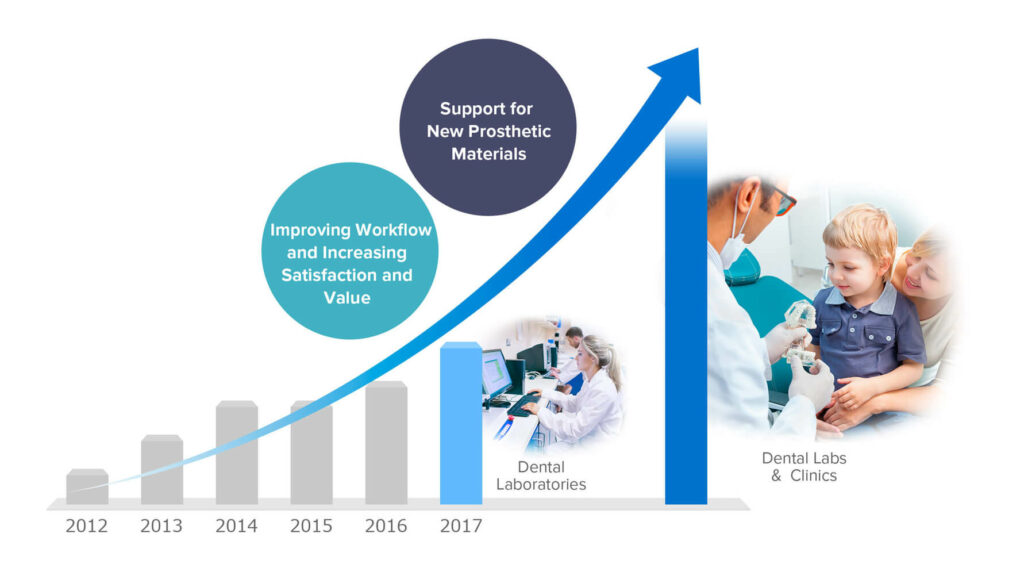

By providing digital solutions for dental technicians, DGSHAPE contributes to helping dental laboratories take advantage of the benefits brought by digitalization, including reliable, high-quality production on demand in a short time. In the field of dental prosthetics, advances in digital technology and materials, including zirconia, composite resins, and glass ceramics, are leading to more and more dental laboratories and clinics installing digital systems consisting of CAD/CAM software and milling machines to replace conventional casting methods. Believing that its technologies and know-how related to 3D milling could contribute to improving the workflow of dental laboratories, Roland DG entered the market in 2010. In 2017, Roland DG transferred its 3D business to a newly-established, wholly-owned subsidiary, DGSHAPE Corporation, to dedicate more time, energy, and staff solely toward the development of innovative dental and other 3D solutions. Today, DGSHAPE continues to expand its customer base by offering solutions to dental laboratories all over the world. Going forward, the company intends to extend the scope of its business to include dental clinics.

DWX Milling Machines

Dental milling machines has been highly praised for its advanced machining precision as well as its desktop size, user-friendliness, open architecture for use in combination with popular CAD/CAM software and scanners, and affordable price, and is used in dental laboratories around the world. The current lineup includes three dry mills, plus one wet mill which is specially designed for milling glass ceramics, a material that is gaining support from dental clinics and patients for its superior hardness and aesthetic qualities.

Dental Business Strategy

As technology continues to revolutionize the dental field, an increasing number of dental laboratories are installing digital systems consisting of CAD/CAM software and milling machines to replace conventional casting methods. New materials for dental prosthetics have also appeared, such as zirconia, composite resins and glass ceramics, and there has been an accelerated increase in the installation of digital systems for efficient processing of these materials.

Manufacturers who provide systems like these often sell closed systems comprised of sets of scanners to capture the contours of the tooth, CAD/CAM software, milling machines and proprietary materials which created a barrier to the installation of digital systems for dental laboratories concerned with a large initial investment and the low degree of freedom in choosing the materials they preferred to provide to dental clinics and patients.

Within this market environment, Roland DG launched the dental milling machines in 2010 to apply its 3D milling technologies cultivated over a quarter of a century. The milling machines at once established Roland DG’s presence in the market and was highly regarded for its desktop size, user-friendliness, open architecture for use in combination with popular CAD/CAM software and scanners, and affordable price. Today, dental milling machines are widely adopted in dental laboratories around the world and are contributing to streamlining the workflow of dental prosthesis production.

As it works toward future business expansion, DGSHAPE is promoting activities to reach the mid-term objectives of “strengthening the ability to support new dental materials,” “acceleration of global expansion” and “developing high value-added solution for the dental industry” In the dental market, an important requirement for DGSHAPE is to support new materials. We therefore pay close attention to the new product offerings of material manufacturers and the needs of patients and dental clinics in order to offer optimal processing methods as quickly as possible. Meanwhile, in dental laboratories, much prosthetic production work is still carried out manually and it is obvious that there are more opportunities where DGSHAPE’s digital solutions can improve the workflow and add value. We are committed to developing and providing optimal digital solutions for further growth in the dental industry.

Message from the President of Roland DG Corporation

Message from the President

Since Roland DG Corporation was founded in 1981, our mission has been “Bringing new opportunities to society through digital technologies.” As personal computers were developed and digitalization spread throughout all types of industries, we have experienced growth through the development of innovative computer peripherals.

Our business began by developing pen plotters based on using XY axis control to output design drawings and architectural schematics created on computers. We subsequently expanded its business by replacing pens with cutters thereby producing vinyl cutters, by adding color management technology to produce wide-format printers and by adding Z-axis control and end mills to produce 3D milling machines. We have created and expanded several new markets by fostering innovation, creativity and added value with the result of becoming a world leader in inkjet printing, vinyl cutting, 3D modeling, rotary engraving and dental milling.

In recent years we have been expanding the scope of our business domains and crafting new business models, with a key focus on our two pillars of business: Digital Printing that delivers the potential of on-demand printing across a broad range of fields with our mainline inkjet printers; and DGSHAPE that provides solutions for promoting efficiency of fabrication in various fields by utilizing 3D digital data and for taking advantage of the benefits brought by digitalization at dental laboratories and throughout other healthcare industries.

Going forward, we intend to continue being an innovative company by providing industry and world-first products and solutions, while enhancing the company more valuable by shifting our perspective.

I would be deeply honored to receive your continued support and encouragement.

Kohei Tanabe

President, Representative Director

DGSHAPE, with the DWX series of dental milling machines, has rapidly established a presence in the market. In addition to their affordability, the devices are appreciated by dental technicians all over the world for their compact size, ease of use and open architecture system that allows them to work with any other product already in the laboratory’s possession: 3D scanners, computers, CAD and CAM software on the market.

More than 15,000 units have been sold worldwide and important communities have been created around the DGSHAPE world at Roland Company: we look forward to seeing you. DGSHAPECrew: Together is Better!